the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

FarmConners wind farm flow control benchmark – Part 1: Blind test results

Filippo Campagnolo

Thomas Duc

Irene Eguinoa

Søren Juhl Andersen

Vlaho Petrović

Lejla Imširović

Robert Braunbehrens

Jaime Liew

Mads Baungaard

Maarten Paul van der Laan

Guowei Qian

Maria Aparicio-Sanchez

Rubén González-Lope

Vinit V. Dighe

Marcus Becker

Maarten J. van den Broek

Jan-Willem van Wingerden

Adam Stock

Matthew Cole

Renzo Ruisi

Ervin Bossanyi

Niklas Requate

Simon Strnad

Jonas Schmidt

Lukas Vollmer

Ishaan Sood

Johan Meyers

Wind farm flow control (WFFC) is a topic of interest at several research institutes and industry and certification agencies worldwide. For reliable performance assessment of the technology, the efficiency and the capability of the models applied to WFFC should be carefully evaluated. To address that, the FarmConners consortium has launched a common benchmark for code comparison under controlled operation to demonstrate its potential benefits, such as increased power production. The benchmark builds on available data sets from previous field campaigns, wind tunnel experiments, and high-fidelity simulations. Within that database, four blind tests are defined and 13 participants in total have submitted results for the analysis of single and multiple wakes under WFFC. Here, we present Part I of the FarmConners benchmark results, focusing on the blind tests with large-scale rotors. The observations and/or the model outcomes are evaluated via direct power comparisons at the upstream and downstream turbine(s), as well as the power gain at the wind farm level under wake steering control strategy. Additionally, wake loss reduction is also analysed to support the power performance comparison, where relevant. The majority of the participating models show good agreement with the observations or the reference high-fidelity simulations, especially for lower degrees of upstream misalignment and narrow wake sector. However, the benchmark clearly highlights the importance of the calibration procedure for control-oriented models. The potential effects of limited controlled operation data in calibration are particularly visible via frequent model mismatch for highly deflected wakes, as well as the power loss at the controlled turbine(s). In addition to the flow modelling, the sensitivity of the predicted WFFC benefits to the turbine representation and the implementation of the controller is also underlined. The FarmConners benchmark is the first of its kind to bring a wide variety of data sets, control settings, and model complexities for the (initial) assessment of farm flow control benefits. It forms an important basis for more detailed benchmarks in the future with extended control objectives to assess the true value of WFFC.

- Article

(9855 KB) - Full-text XML

- BibTeX

- EndNote

Wind farm flow control (WFFC) promises to mitigate the losses due to aerodynamic turbine–turbine interactions and can potentially provide several benefits to reduce the cost of energy in the design and operation of wind farms. Its most prominent benefits are the potential increase in power production and/or alleviation of turbine structural loading at wind farms by reducing wake losses and encouraging energy entrainment into the farm. The phenomenon has been thoroughly investigated, with lower-order and high-fidelity flow and structural response models (e.g. Gebraad et al., 2016; Munters and Meyers, 2018; Duc et al., 2019; Hulsman et al., 2020), wind tunnel tests (e.g. Rockel et al., 2017; Bastankhah and Porté-Agel, 2019; Campagnolo et al., 2020; Bottasso and Campagnolo, 2021), and field experiments (e.g. Fleming et al., 2017; Annoni et al., 2018; Doekemeijer et al., 2021; Bossanyi and Ruisi, 2021; Simley et al., 2021). A comprehensive review of the power maximization through WFFC is presented in Kheirabadi and Nagamune (2019) and Andersson et al. (2021). To realize those benefits, the control strategy might be

-

axial induction control, in which some upstream turbines will lower their energy capture (also referred to as curtailment, down-regulation, or derating), hence increasing the wind velocity and reducing the turbulence downstream;

-

wake steering, in which some of the turbines will be misaligned to redirect the wake away from the other turbines, hence mitigating the wake effects; and

-

wake mixing where upstream turbines are dynamically up-regulated and down-regulated on short timescales to induce additional wake mixing and wake recovery, minimizing the losses further downstream.

A number of control-oriented models with different levels of complexity have been proposed in literature to implement those control strategies, but uncertainty remains high and a systematic validation and comparison under different control settings have been lacking. Validation and industrial implementation, in fact, is identified as one of the four key challenges within the WFFC field and thoroughly discussed in Meyers et al. (2022), where an in-depth review of the relevant studies is also presented.

In order to assess the performance of the WFFC technology, the capabilities of WFFC models should be evaluated. Accordingly, the FarmConners consortium (FarmConners, 2019) has launched a common benchmark for code comparison, where high-fidelity simulation results, wind tunnel experiments, and field data measured at a full-scale wind farm are brought together. This unique database combines the efforts of the connected WFFC projects of different sizes all over Europe and consists of four blind tests in total: (1) SMARTEOLE Sole du Moulin Vieux (SMV) field measurement campaign (Duc et al., 2019), (2) CL-Windcon wind tunnel experiments (CL-Windcon, 2016), (3) CL-Windcon large-eddy simulations (LESs) (CL-Windcon, 2016), and (4) TotalControl LES (TotalControl, 2018). Every data set is divided into a “calibration” and a “blind test” period to resemble field application of WFFC models. The calibration period involves both input and output features which can be used to calibrate the participating models under normal operation and limited control set points. In the blind test period, the calibrated models are to be run “blindly”, where only the input features are provided and their outputs are compared against the validation data set or the blind test reference, as well as each other.

Promoting data sharing and standardization for validation processes as well, one of the most relevant exercises with similar structure is Wakebench (Rodrigo et al., 2014; Moriarty et al., 2014), focusing on wind farm flow modelling under normal operation. Although sharing similar goals, the FarmConners benchmark blind tests conduct the performance evaluation exclusively under controlled operation. Therefore, the two benchmarks diverge in terms of test cases, quantities of interests and the validation metrics. However, the lessons learned from the extensive Wakebench experience (Doubrawa et al., 2020) is attentively taken into consideration while preparing the framework, aiming to extend the standard verification and validation (V&V) practices to include WFFC in wake research, globally.

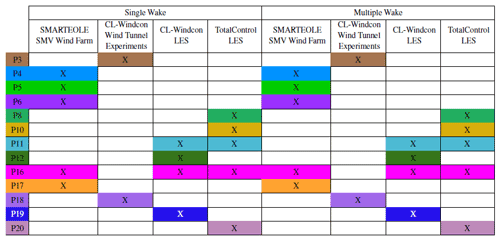

The FarmConners benchmark is launched in TORQUE 2020 (Göçmen et al., 2020a), and in the end, 13 participants have submitted the results from their models, taking part in different blind tests. The overview of participants among the benchmark blind tests is presented in Table 1, and it should be noted that some participants have provided results from several models. The primary quantities of interest used in the model evaluations are the direct power comparisons at upstream and downstream turbines, as well as the power gain at the wind farm level by applying wake steering control strategy. Additional analysis on the wake loss reduction has also been presented to support the evaluation of the power performance, where relevant. It should be noted that the potential of the structural load alleviation, which was originally a quantity of interest in the benchmark, has been excluded from this study. This is due not only to the limited number of participating models capable of providing the necessary channels, but also to keep the focus on the most important benefit of the WFFC technology, as reported in the expert elicitation survey (van Wingerden et al., 2020). Similarly, scenarios with axial induction control that were included in the majority of the blind tests originally are also omitted due to limited participating model results. All the data collected for the benchmark can potentially be made available upon request for researchers; see Data availability section for details. The notebooks, including data snippets, where the blind test results are produced are also publicly available; see Code availability section for details.

Table 1Overview of the FarmConners benchmark participants (participant IDs P3–P20) per test case, per blind test. WFFC-oriented model comparison is performed separately for each column. The participants are colour coded for easy access through the article, where CL-Windcon wind tunnel experiments blind test results are discussed in Part 2 of the series.

The analysis and discussion of the results of the benchmark are divided into two parts. Here in Part I, the modelling of the large-scale rotors (blind tests 1, 3, and 4) is investigated, and in Part 2 the blind test results of the wind tunnel experiments are presented. Accordingly, Sect. 2 describes the SMV field campaign and presents the participating model results for single- and multiple-wake scenarios under upstream wake steering. High-fidelity simulations being a key enabler for the industrial implementation of WFFC, the subset of the extensive CL-Windcon LES database used for the FarmConners benchmark is detailed in Sect. 3. The participating models for the CL-Windcon LES blind tests are then evaluated for three and nine-turbine wind farm configurations, with 5- and 7-diameter (D) spacing respectively. Similarly, Sect. 4 utilizes up to eight-turbine subsets of a 32-turbine layout of a reference wind farm developed under the TotalControl project and compares the participating model results with the reference LES database under upstream wake steering.

Here in this article, we present the results from the large-scale rotor analysis of the FarmConners benchmark. The analysis is broken down into blind-test-specific, relatively stand-alone sections with limited cross-references and can be read separately if preferred.

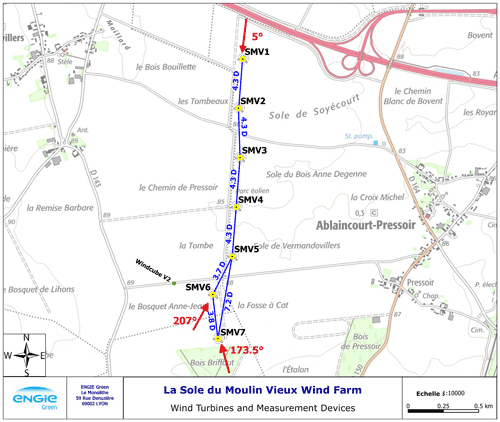

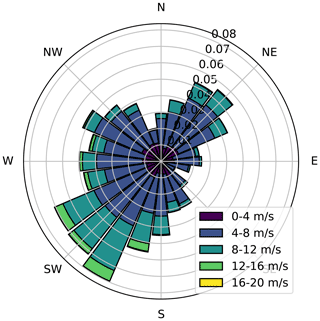

The wind farm field data come from the Sole du Moulin Vieux (SMV) wind farm, located in the northern part of France (approximately midway between Paris and Lille) and operated by ENGIE Green. It consists of seven Senvion MM82 wind turbines (diameter of 82 m, nominal power of 2050 kW, hub height of 80 m; see Duc et al. (2019) for power and thrust coefficient, CT curves), organized in an irregular single row layout and labelled SMV1 to SMV7 from north to south. This wind farm has been used for the field tests of the French national project SMARTEOLE, whose results have been presented in Ahmad et al. (2017) and Duc et al. (2019) for field campaign 1 and in Simley et al. (2021) for field campaign 3. The layout of the wind farm is shown in Fig. 1, and the long-term wind rose observed at the site is presented in Fig. 2.

Figure 1Layout of SMV wind farm. Distances between wind turbines (normalized by their rotor diameter D = 82 m) and directions related to SMV6 and SMV5 are also shown. The location of the Windcube v2 sensor used for field campaign 2 is also indicated.

Figure 2Long-term wind rose for the SMV wind plant at hub height (80 m). It was obtained through a correlation process between short-term met-mast measurements on-site and long-term reference wind data (ERA5 reanalysis data). Taken from Simley et al. (2021).

The data set used for this benchmark exercise corresponds to the experiments carried out during field campaign 2, between May 2017 and March 2018. A ground-based lidar Windcube v2 was installed specifically for these field tests; its location close to SMV6 is displayed in Fig. 1.

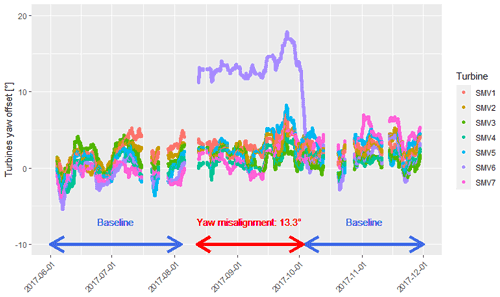

Between 12 August 2017 and 3 October 2017, the SMV6 wind turbine was constantly misaligned for all wind directions. The averaged value of the turbine yaw offset during this 7-week period was −13.3∘ (turbine rotated anticlockwise when viewed from above), as illustrated in Fig. 11 below. This misalignment creates a wake steering that affects the downstream turbines, mostly SMV5 for wind directions between 200 and 215∘ and more slightly SMV4 to SMV1 for wind directions below 200∘.

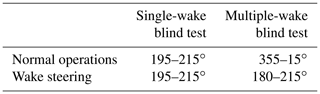

2.1 Calibration and blind test data sets

A total of 12 months of normal operation data, from 1 October 2016 to 30 November 2017 (removing the 2 months for which the wake steering tests were conducted) were provided to the benchmark participants to help them calibrate their wake models. The calibration data consist of 10 min statistics (average, minimum, maximum, and standard deviation) of 10 of the most important variables of supervisory control and data acquisition (SCADA) data, including active power, wind speed and direction, yaw angle, pitch angle, outdoor temperature, and rotor and generator speed.

The data were filtered to keep only timestamps when all wind turbines were operating at the same time. Any timestamps when curtailments were detected in one of the turbines were also removed from the data set. Yaw angle and direction data were corrected for north alignment issues, making sure those signals were consistent over the full period. One turbine experienced a modification of its blade aerodynamic properties during the period. The effect of this change on turbine performance or anemometer wind speed measurement is unknown and could not be corrected.

The available data set for the wake steering experiment was unfortunately limited and could not be split into calibration and blind test subsets. Consequently the participants could only calibrate their wake deficit and superposition models and did not have any data to adjust either the parameters of their wake deflection models or the yaw loss function of the misaligned turbine.

The blind data set was prepared using the same procedure as for the calibration data set. The only difference is that the active power signal was removed for all turbines, and the wind speed signal was removed for all but the upstream turbines (SMV6 for south, south-westerly and SMV1 for northerly directions, indicated in Table 2). The Windcube data provided to the participants cover the full wake steering period and part of the calibration data, starting on 31 May 2017 and ending on 23 January 2018. All heights of measurements, ranging from 40 to 200 m, were kept in the data set. The participants were left free to use these data to calibrate any onsite atmospheric parameters, such as the turbulence intensity or the wind shear.

2.2 Participating models

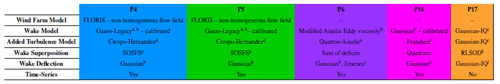

Within the FarmConners benchmark, in total five participants (IDs = P4, P5, P6, P16, P17) have taken part in the SMV wind farm field data blind test. The participating models cover a relatively broad range of assumptions, approximations, and parameters representing the flow behind a steered turbine. Here in this section, these participating models are briefly described, and implemented parameters are listed when relevant. Table 3 summarizes the prominent characteristics of the participating models. However, it should be noted that a seemingly identical model applied by the participants is likely to be calibrated differently, resulting in different performance in their predictions. This is further discussed in the detailed model descriptions per participant and highlighted in the blind test results later in the section.

Table 3Overview of the participating WFFC-oriented models, wind farm field data blind test. a Bastankhah and Porté-Agel (2014). b Ainslie (1988). c Ishihara and Qian (2018). d Crespo and Hernández (1996). e Quarton and Ainslie (1990) – with sum of difference. f Frandsen (2007) – IEC 2019 standard. g SOSFS – sum of squares free-stream superposition. h Bastankhah and Porté-Agel (2016). i Jiménez et al. (2010). j Qian and Ishihara (2018). k RLSOD – rotor-based linear sum of deficits.

2.2.1 P4

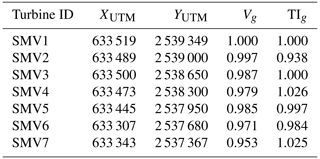

Wind speed and turbulence intensity. The wind speed was defined using nacelle anemometers at each wind turbine. The turbulence intensity was calculated using the mean and standard deviation of the anemometer data for each wind turbine.

Wind direction. It has been assumed that the average of the directions indicated by turbines' wind vanes was a good estimate of the free wind. The multiple-wake simulations used the average of all wind turbines measurements, and the single-wake simulations averaged SMV5 and SMV6 direction data.

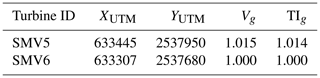

Heterogeneous flow. The non-homogeneous flow field in the steady simulation was obtained through speed factors between turbines in free sectors (Vg – velocity factor, TIg – turbulence intensity factor). The factors were obtained using the wind turbine anemometer measurements, and they were applied regardless of the wind direction. These factors were defined with respect to the reference free wind turbine (SMV1 in multiple-wake case – Table 4 and SMV6 in single-wake case – Table 5).

Free-stream wind speed and turbulence. The free-stream turbine conditions for the blind test simulations were determined by the free-stream turbines (SMV1 in multiple-wake case and SMV6 in single-wake case). For calibration, the free-stream wind speed and turbulence intensity were obtained averaging the free-stream turbines depending on the orientation. The heterogeneous factors were taken into account in order to refer the magnitudes to SMV1 (reference wind turbine for the multiple wake).

Wake model. The calibration performed by P4 was based on the FLORIS model, using the Gaussian velocity deficit model by Bastankhah and Porté-Agel (2014), and wake-added turbulence was modelled with the Crespo-Hernández model (Crespo and Hernández, 1996). The combination model selected was “SOSFS”, which uses sum of squares free-stream superposition to combine the wake velocity deficits to the base flow field (Katic et al., 1986). The yaw steering is represented by the deflection model Bastankhah and Porté-Agel (2016).

Calibration. The calibration process was performed using normal operation with multiple-wake data. The data were discretized with respect to the assumed wind direction (average of all wind turbines, bin size = 5∘) and free wind speed bins (bin size = 2 m s−1). From these data, a calibration matrix was created, by extracting mean values for velocity, turbulence intensity, and power in each wind turbine. Only cases where there is a wake effect were included in the calibration matrix. The calibration was performed using a genetic algorithm to obtain wake velocity and wake turbulence parameters. The parameters obtained in this process are presented in Table 6.

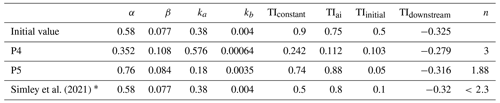

Simley et al. (2021)Table 6Calibrated parameters of the used velocity and turbulence sub-models of the relevant models used by participants P4 and P5, where α and β; ka and kb; and TIconstant, TIai, TIinitial, and TIdownstream are model parameters in FLORIS (NREL, 2021), and n is the yaw loss exponent in Eq. (1). * In Simley et al. (2021), the wake model fitting was realized by tuning the ambient turbulence intensity value rather than updating the model parameters. Within FLORIS (NREL, 2021), the Gauss velocity model (Bastankhah and Porté-Agel, 2014, 2016; Blondel and Cathelain, 2020; King et al., 2021) was used rather than the Gauss legacy model (Bastankhah and Porté-Agel, 2014, 2016) as for P4 and P5.

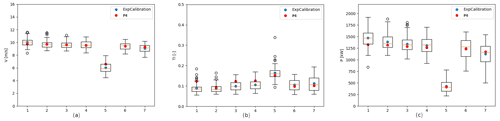

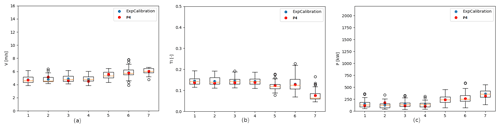

The comparison between the original experimental data, the average values used for calibration, and the simulation with the final calibrated parameters can be observed for specific wind conditions in Figs. 3 and 4, as illustrative examples. The original experimental data are shown as a boxplot, representing the median of the magnitudes and the dispersion of the data. The calibration values and the final simulation are represented by points for each wind turbine. Figure 3 presents the results for the bin centred in direction = 210∘ and wind speed = 10 m s−1, where the wake is evident for wind turbine SMV5 (single-wake sector). The agreement in the values in terms of velocity, turbulence intensity, and power is evident for wind turbine SMV5. Figure 4 presents results for the bin centred in direction = 185∘ and wind speed = 6 m s−1, where wind turbine SMV7 shows higher power and wind velocity than the rest of the turbines. The agreement in terms of velocity, turbulence intensity, and power is clear.

Figure 3P4: the y axes show (a) velocity (m s−1), (b) turbulence intensity (TI, –), and (c) power (P, kW). Comparison per SMV wind turbine (turbine numbering SMV1–SMV7 in x axis) between experimental data (boxplot), average values used for experimental calibration (ExpCalibration, blue circles), and simulation with calibrated parameters (P4, red circles). Bin direction = 210∘; bin wind speed = 10 m s−1. Empty black circles represent outliers.

Figure 4P4: the y axes show (a) velocity (m s−1), (b) turbulence intensity (TI, –), and (c) power (P, kW). Comparison per SMV wind turbine (turbine numbering SMV1–SMV7 on the x axis) between experimental data (boxplot), average values used for experimental calibration (ExpCalibration, blue circles), and simulation with calibrated parameters (P4, red circles). Bin direction = 185∘; bin wind speed = 6 m s−1. Empty black circles represent outliers.

FLORIS deflection parameters were not calibrated: the default parameters were used during calibration and subsequent simulation of the results. On the steered turbine, the power loss due to misalignment was modelled via the yaw loss function in Eq. (1), where Ψ is the steering control setting and n is the yaw loss exponent, as stated in Table 6. There are several values proposed for n depending on the experimental setup and the turbine type, where n=3 is typically considered based on blade element momentum (BEM) theory as well as numerous wind tunnel experiments (Krogstad and Adaramola, 2012; Bartl et al., 2018b, a), n=1.8 is proposed by other wind tunnel experiments (Schreiber et al., 2017) and LES (Draper et al., 2018), n=1.88 was considered in Gebraad et al. (2016), and n=1.4 was used in Fleming et al. (2014). Further discussion on varying n within the wind farm (based on upstream and downstream turbine configurations) can be found in Liew et al. (2020b).

The yaw loss exponent could not be calibrated, and the value for the simulations was set as n=3. In the blind test simulations, the yaw misalignment time-series data were used instead of using the intervals or average values.

It should be noted that the potential effects of atmospheric stability, shear, and veer were not taken into account in the P4 simulations, and tilt angle of the wind turbines was neglected. The parameters listed in Table 6 follow the abbreviation convention in the FLORIS repository (NREL, 2021).

2.2.2 P5

The baseline engineering flow model FLORIS (NREL, 2021) was adapted to the site by introducing parametric correction terms, which are learned from the available training SCADA data.

Preparation of the calibration data set. The tuning of the engineering model was performed using the provided calibration data set. As FLORIS is a steady-state model, some of the SCADA data were discarded by looking at the nacelle position measurements, with the aim of only using data characterized by fairly steady and uniform inflow and operating conditions. Specifically, a 10 min SCADA data point was discarded if

-

the variation in the nacelle orientation of any turbine between two consecutive timestamps exceeds 20∘, so as to discard data measured under strongly varying wind direction;

-

the deviation of the nacelle orientation of any turbine from the average pointing direction of the entire wind farm exceeds 20∘, so as to discard data measured under highly non-homogeneous wind direction;

-

the standard deviation of the nacelle orientation of any waked turbine was not null, so as to discard data recorded while one of the waked turbines was yawing during the 10 min period.

Determination of the ambient wind conditions. Once the data were prepared, it was possible to estimate the ambient wind conditions to be used as input to the engineering model. First, the ambient wind direction in each timestamp was calculated by computing the average of the wind directions measured with the turbines' wind vanes. Only observations within the southern 175–220∘ and northern 350–20∘ sector were kept. Overall, 5329 data points (≈ 15.4 % of the calibration subset) for each of the seven turbines were used for calibrating the flow model.

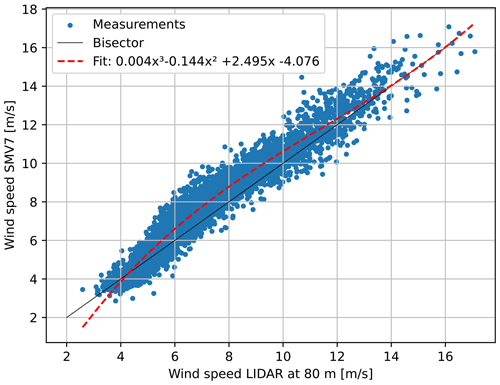

Free-stream turbines were used to determine inflow wind speed and turbulence. The wind speed was reconstructed from the turbine power, while the turbulence was computed using the mean and standard deviation values of the nacelle anemometer recordings. The determination of whether a turbine operates in free stream or not was based on the wind farm layout and inflow wind direction, thus following the recommendations given in International Electrotechnical Commission (2005). For wind directions in the sector between 345–25∘, measurements from SMV1 were therefore used. Measurements from SMV6 were instead used for wind directions between 195–225∘. For wind directions between 170–195∘, corrected measurements from SMV7 were used, since it was expected that its sensed wind speed would be affected by the nearby forest. In detail, a third-order polynomial function was best fit to the ratio between the wind speed measured by the Windcube v2 at 80 m and the wind speed measured by the SMV7 anemometer, while both were operating in free-stream conditions. Details of the fit are specified in Fig. 5. The resulting correction, scheduled as a function of the SMV7 anemometer measurement, was then applied to both the calibration and blind test subsets.

Figure 5Comparison of wind speed measured by the Windcube lidar at 80 m height and the nacelle wind speed of SMV7 in the sector 170–195∘. Fit statistics performed by P5: R2 = 0.94, σ=0.54 m s−1.

As for the wind shear, a constant value of 0.25 was used, which corresponds to the average of the shears measured by the Windcube v2.

Finally, the complete data set was binned over wind speed and wind direction in bins of 1 m s−1 and 1∘ respectively so as to further reduce the measurement noise and speed up the tuning process.

Tuning parameters and process. The velocity deficit was modelled with the kinematic Gaussian velocity deficit model by Bastankhah and Porté-Agel (2014) and the root sum of squared deficits superposition model (Katic et al., 1986). Wake-added turbulence was modelled with the Crespo and Hernández (1996) turbulence model and deflection through the Bastankhah and Porté-Agel (2016) deflection model. The model calibration parameters that describe the wake velocity and wake turbulence models were further corrected in the tuning process, whereas for the wake deflection model the default FLORIS values were used. In addition to that, the exponent n of the cosine law (Eq. 1) used to model the power losses of yawed turbines was set to 1.88, i.e the value adopted by Gebraad et al. (2016).

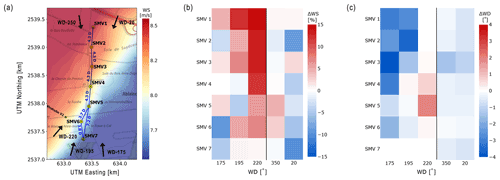

As the incoming wind is permanently affected by the local orography and vegetation, it is necessary to account for the long-term spatial variability of both wind speed and wind direction. To achieve that, a heterogeneous flow field is parameterized in terms of shape functions and associated unknown speed-up (ΔWS) and wind direction (ΔWD) nodal values (Schreiber et al., 2020). The nodes were placed at the coordinates of the turbines, and the resulting mesh was further discretized for five different inflow wind directions. This resulted in seven nodes for each of the considered inflow wind directions (WD-20∘, WD-175∘, WD-195∘, WD-220∘, and WD-350∘), leading to a total of 35 speed-up and 35 wind direction nodes. The desired flow correction is then obtained by mapping the nodal values, with associated linear shape functions, to the locations of interest. The distribution of the nodes in terms of location and direction can be seen in Fig. 6a, which also depicts the resulting background flow field for an inflow speed of 7.56 m s−1 and a wind direction equal to 214.7∘.

Figure 6(a) Wind speed and direction node locations within the cluster. (b) Identified speed-up (ΔWS) nodal values. (c) Identified wind direction (ΔWD) nodal values.

The intrinsic parameters of the adopted wake and turbulence sub-models were identified together with the heterogeneous flow nodal quantities, resulting in a site-specific coupled simultaneous correction and tuning of the model. This ill-conditioned optimization problem was solved by mapping the unknown parameters into an orthogonal space via the singular value decomposition (SVD), solving the identification by a maximum likelihood estimation in the reduced space and then mapping back the solution to the physical space (Schreiber et al., 2020). The identified, tuned parameters for the wake model are shown in Table 6, while Fig. 6b and c show the identified speed-up and wind direction nodal values. For further details on the description of model parameters, see NREL (2021). For further discussion on the significance of such a parameterization, see e.g. van Beek et al. (2021).

2.2.3 P6

Atmospheric conditions at the site. The provided SCADA data covering the calibration period were used to model the site’s characteristics and perform preliminary comparisons.

Wind direction. The wind rose obtained from the calibration period data is similar to the one shown in Fig. 2 and contains a large portion of data for which no yaw offset is reported (about 65 %), whereas the remaining 12046 data points report a yaw offset. The ranges of wind direction that occurred during the provided blind test SCADA data are reported in Table 2. The yaw offsets during the calibration phase (calculated as the difference between the Windcube v2 lidar directional data at hub height and turbine SMV6’s nacelle-corrected heading) have a mean value of −13.3∘, with values ranging from −26 to +30∘.

Wind speed. The only available source of wind speed for both the calibration data set and the blind test data set is the nacelle-mounted anemometers at each turbine, if the Windcube v2 lidar is excluded. Preliminary correlations between the lidar's and turbine SMV6's wind speed signals showed a non-linear relationship and significant amount of scattering, suggesting the underestimation of wind speeds by the nacelle-mounted anemometers, especially for wind speeds lower than 10 m s−1 (as measured by the lidar). As explained in the next section, transfer functions have been used to convert wind speeds from anemometers to free-stream wind speeds using the measured active power and the provided warranted power curve. Additionally, directional correlations between different turbines have been used to obtain a table of wind speed corrections that represent the variation in wind speed at the site (also known as speed-ups). It is also stressed that any estimation of the wind farm blockage effect has not been attempted.

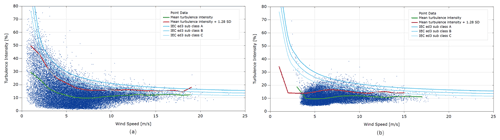

Atmospheric turbulence intensity. The variation in turbulence intensity with wind speed is shown in Fig. 7 as measured from both the lidar and turbine SMV6. Both the mean and the P90 turbulence levels in the two plots show some similarities, especially for wind speeds above approximately 7.5 m s−1. Although the correlation between the wind speed standard deviation at the lidar and SMV6’s nacelle-mounted anemometers shows significant scattering (not shown here), using the 10 min averaged wind standard deviation from the SCADA data is considered to be broadly suitable in this case for the purpose of wake modelling, as also pointed out in Duc et al. (2019). It is noted that the SCADA wind speed standard deviation data have not been used to obtain any turbine-specific turbulence intensity correction across the site, as was done for the wind speeds.

Figure 7Turbulence intensity (%) measured by (a) Windcube v2 at 80 m and (b) turbine SMV6 vs. wind speed (m s−1).

Air density. Historical atmospheric data have been obtained from ERA5 and NEWA reanalysis data sets at the closest available nodes to the site. The long-term averaged air density at the site was found to be 1.23 kg m−3, with values ranging between 1.13 and 1.35 kg m−3. These values have been used to correct the power curve in the simulations (see below).

Wind shear. The lidar measurements were provided at different heights and for a period of about 8 months. The two measurements closest to the low tip and high tip of the rotor (40 and 120 m respectively) have been used to estimate the average shear profile across the turbine rotor. Assuming the directional wind shear estimations at the lidar location are representative for all turbine locations (except for the directions with the wake effects), power-law exponents 0.178 and 0.268, respectively corresponding to wind direction bins centred at 0 and 210∘, have been used for the blind test simulations based on each case's wind direction range (see Table 2).

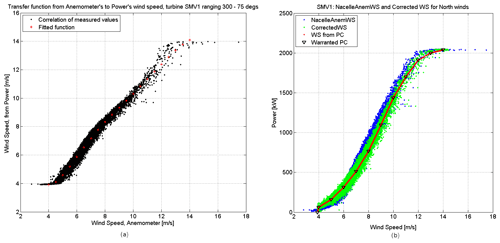

Calibration of turbine characteristics. The first step for the calibration process was to focus on data representative of normal operations only by filtering out any data recorded when yaw misalignment was present. The variation in wind speeds across the turbine locations was pragmatically estimated from correlations between the turbines' SCADA data, only from the two main directions of interest for the blind tests, in Table 2. In order to exclude the sectors with the wake effects and have enough data points, the SCADA wind speed signals at each turbine were filtered for broader directional sectors around the aligned directions with the wake effects. By using SMV1 and SMV6 as reference turbines for the north and the south wind direction cases respectively, correlations between each turbine and each reference turbine were performed for the filtered wind directions, in order to find speed-up factors describing the local variation in free wind speeds for the directions of interest. The obtained values were used to define these effects for the excluded directions with the wake effects, by averaging the valid directional values. An example of this approach is given in Fig. 8.

Figure 8(a) Rotor effective vs. nacelle anemometer wind speed (m s−1): Fitting between anemometer and power-based wind speeds at turbine SMV1 for northern wind speeds under rated power. (b) Power (kW) vs. wind speed (m s−1): comparison at turbine SMV1 between warranted power curve (PC), power based on anemometer wind speeds, and corrected power curve using the transfer function as described.

The turbine’s wind speed standard deviation values were assumed to be representative of the free atmospheric conditions, as described in the previous section, and have therefore been used for the definition of turbulent intensity.

Plotting the active power against the wind speeds from the nacelle-mounted anemometers for each turbine, large differences emerge when compared to the provided warranted power curve. The wind speed could be back-calculated from the active power SCADA signal; however, this signal is only provided for the calibration data set and not as part of the blind test package. Since at least one turbine’s SCADA wind speed signal was made available for each blind test scenario, the available calibration data set was used to create a transfer function linking nacelle anemometers' measurements and wind speeds back-calculated from active power, exclusively for the wind directions of interest. This was achieved, for each turbine, by using a sixth-order polynomial fitting process for SCADA wind speeds ranging between cut-in and rated wind speeds, hence covering the whole wind speed range in all the blind test scenarios analysed.

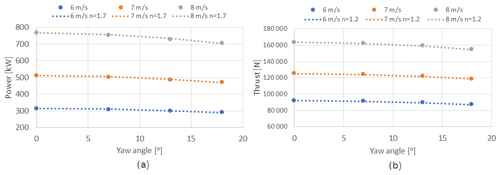

In order to calibrate the power curves from the available data recorded when yaw misalignment was present, the data were binned for different yaw angle ranges. Due to the limited amount of data recorded during the yaw misalignment tests, it was decided to focus specifically on three misalignment angles, −7, −13.3, and −18∘, deemed to be representative of the distribution of measured yaw misalignment angles during the blind tests. A power curve for each of these angles was obtained by fitting the data clustered in these three bins, and the thrust curves were also adapted to the yawed cases by applying the same wind speed shift found for the power curves. It is noted that the commonly used approach of modifying the power and thrust values by multiplying these by a factor such as cos(Ψ)n (where n is a positive real number and Ψ is the turbine yaw angle, as shown in Eq. 1) has not been used in this instance, also due to the large uncertainty given by the large range of exponent values found in literature. For completeness, a comparison between the calibrated power and thrust curves and the best-fitting cosine exponents (respectively being found to be 1.7 and 1.2) is shown in Fig. 9 for wind speeds of 6, 7, and 8 m s−1.

Figure 9(a) Power and (b) thrust values obtained from data calibration at three wind speed values and at four yaw misalignment settings, compared to a cos(Ψ)n function.

Wake modelling. Different wake modelling approaches have been tested for this specific site. The chosen steady-state model utilized, in a time-series fashion, for producing the results presented in this report is based on the Ainslie model (Ainslie, 1988), including modifications suggested by Anderson (2009) and Ruisi and Bossanyi (2019). The wake-added turbulence was modelled using the Quarton and Ainslie (1990) model, and for the superposition of wake effects the sum of deficits method is used for the velocity deficits, and sum of variances is used for turbulence superposition. The time series of air densities has been used to correct the power curve during simulations, as prescribed by the IEC standards. The rotor-averaged quantities have been calculated by taking into account the directional wind shear across the rotor, as explained in the previous section. Furthermore, it is noted that the effects of wind farm blockage, atmospheric stability, and veer have not been taken into account for the purpose of wake modelling at this site.

The model used for this simulation is the one by Bastankhah and Porté-Agel (2016), where the four numerical parameters used in the model were not calibrated (hence were kept the same as reported in the original article); however an additional factor of 2 is added to the formula predicting the skew angle in Eq. (6.12) in Bastankhah and Porté-Agel (2016) (as implemented also in FLORIS NREL, 2021). This version of the model was preferred to the same model with the exclusion of this additional skew factor, or the model by Jimenez (Jiménez et al., 2010) for which the characteristic parameter k was set to 0.05 (as opposed to 0.15, as suggested in the original article), based on previous experience with other calibration data sets.

2.2.4 P16

P16 results are obtained using an in-house wake modelling code. The calculations are based on single-wake superposition with the Bastankhah and Porté-Agel (2016) wake model, capable of modelling yaw deflection. The model parameters are optimized based on the provided calibration data set under normal SMV wind farm operation, using the SGA optimizer of the “pygmo” library (Biscani and Izzo, 2020). For the optimization run, the data were filtered for wind directions coming from the north, reflecting the multiple-wake case. Influences of orography and forest, resulting in an in-homogeneous wind field, were not taken into account. Wind speed, wind direction, and TI values from the upstream turbine (SMV1) were directly used for the definition of the ambient wind field. The parameters of the wake model were obtained by minimizing the sum of the average quadratic differences between power measurements and simulated power at every turbine of the wind farm. The following parameters were results of the optimization and used for further modelling: ka=0.234, kb=0.0037 and α = 4.967, β=0.0015. Those are principally the same model parameters as described for the other participants in Table 6, described in detail in Bastankhah and Porté-Agel (2016), but implemented in a different framework than FLORIS. Measurement uncertainties were not taken into account for the model calibration. We expect the high value of α, compared to literature studies, to be a reflection of the general uncertainty, especially of the wind direction measurement. As a large α leads to quite short near-wake lengths, which are essential for the magnitude of wake deflection in the deflection model, we expect the wake deflection with these parameters to be quite inefficient. For the yawed turbine, the power loss is modelled via Eq. (1) with n=1.88, and the change of CT with yaw is modelled analogously with an exponent of n = 1. This assumption was made due to the unknown behaviour of the turbine in yaw and based on Fleming et al. (2014).

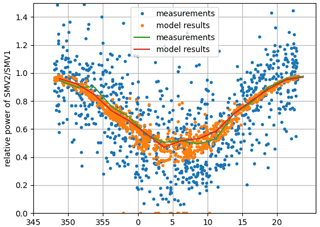

Since there is no general agreement in literature, we expect the modelling of the turbine performance in yaw to be a large uncertainty factor. The multiple wakes are superposed via the quadratic sum of their deficits, and the rotor effective wind speed is calculated as the weighted sum at 19 points over the rotor. The wake-added turbulence intensity is modelled with the Frandsen (2007) model. Figure 10 shows the relative power of SMV2 compared to SMV1 for the data which were used for calibration of the model. In general, the mean wake losses show a good agreement with the measured data considering that the spread of the measured data is naturally higher due to measurement uncertainties.

Figure 10Comparison of measurements and P16 model outputs for calibration period, SMV2 compared to SMV1. The y axis shows relative power of SMV2 and SMV1, and the x axis indicates the incoming wind direction in (∘). Solid lines are the binned average of the measurements and model results indicated as scatters.

2.2.5 P17

Wake model description. A modified Gaussian wake model named Gaussian-IQ, which provides three-dimensional wake characteristics including wake width, velocity deficit, added turbulence (Ishihara and Qian, 2018), and wake deflection caused by yaw offset (Qian and Ishihara, 2018), is utilized by P17. Parameters that govern the evolution of wake in the Gaussian-IQ model are determined as the function of thrust coefficient and local hub-height turbulence intensity. No additional calibration of model parameters has been added, and the default values were utilized. To combine velocity deficits of multiple wakes, the rotor-based linear sum (RLS) is employed. For turbulence intensity in the multiple wakes, it is formulated based on the principle of a linear sum of square (LSS) with an additional correction term to consider the effects of wake interaction (Qian and Ishihara, 2021).

Turbine model description. The theoretical power and thrust curves of Senvion MM82 at the site are used to determine the turbine performance under normal operating conditions for an air density of 1.225 kg m−3. For the steered turbine, to model the power loss and thrust force change due to the yaw misalignment, an effective wind speed is introduced to power and thrust look-up tables, following the approach recommended by Ruisi and Bossanyi (2019), feeding into Eq. (1) as , where Ψ is the yaw offset angle and n is the yaw loss exponent set to 1.88, which is the value suggested by Gebraad et al. (2016).

Simulation process. The wind farm simulation is performed in steady state, and results are provided via a data set binned over wind speed and wind direction (WD) in bins of 1 m s−1 and 5∘ respectively. For each wind speed, the binned values with respect to, for example WD = 5∘, are obtained by taking the average of the results from 10 simulations of WD = 2.5∘. The wind speed, wind direction, and turbulence intensity (TI) in the axial direction are assumed to be homogeneously distributed in the wind farm. A wind shear profile following the power law with a constant exponent of 0.15 is applied to the inflow wind speed. As shown in Fig. 7, the variation in turbulence intensity with wind speed measured by the free-stream turbine SMV6 is quite stable for wind speeds above approximately 4 m s−1. Thus, the ambient turbulence level at hub height is set to be constant with the mean value of TI = 0.11.

2.3 Validation data pre-processing

The wind farm field data blind tests are prepared as single and multiple wakes, where the upstream turbine SMV6 was steered with −13.3∘ mean with respect to the incoming south-westerly wind. The results are evaluated in terms of balanced energy gains, as defined in Fleming et al. (2019). Since the experiments were not realized in the form of a toggle test, the baseline case is taken by considering two 2-month periods before and after the field tests, as shown in Fig. 11.

Figure 11Evolution of the yaw offset of all turbines in the farm during the period of the analysis. The reference wind direction is taken from the Windcube lidar. To smooth out the time series, a moving average of 3 d was applied. The periods corresponding to the baseline case and the wake steering case are marked by the arrows. The averaged misalignment angle on the SMV6 turbine is indicated.

The wind speed and direction reference signals for computing the energy ratios come from the Windcube v2. Due to the proximity of this sensor with the controlled turbine, the atmospheric conditions measured should be very similar to the ones faced by SMV6. The reference power signal is issued from the SMV7 wind turbine, which is the only remaining upstream turbine for the southerly wind sector. However, SMV7 is located very close to the forest and therefore experiences a much disturbed wind compared to SMV6. Consequently the SMV7 active power signal must be corrected to be representative of SMV6 in the baseline situation. This is done following the same procedure as explained in Simley et al. (2021); namely under normal operation, SMV6 and SMV7 active power signals are binned against wind speed (1 m s−1 bins) and wind direction (calculated every degree on overlapping 10∘ bins). Then, a transfer function is estimated by dividing the SMV6 averaged power by SMV7 averaged power in each bin. Finally this transfer function is applied to SMV7 power time series to generate a reference power signal used in both the baseline and the wake steering cases for the computation of the energy ratios.

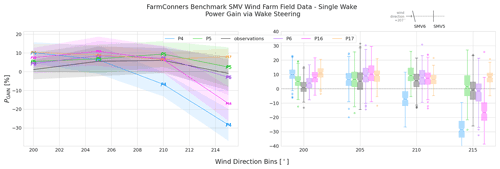

2.4 Single-wake results

For the single-wake case, the estimated and observed performance of the SMV6–SMV5 turbine pair is investigated within a narrow wind sector of 200–215∘ (i.e. ±7.5∘ around the perpendicular direction), where the upstream turbine SMV6 is misaligned for 13–15∘ anticlockwise (negative misalignment with mean ∘). The final data set within that sector for wake steering consists of 216 10 min data points, while the normal operation data set used to calculate the baseline wake effect is made of 1120 10 min data points (484 recorded in June and July 2017, 616 recorded in October and November 2017).

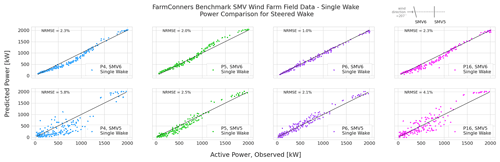

2.4.1 Time-series comparison

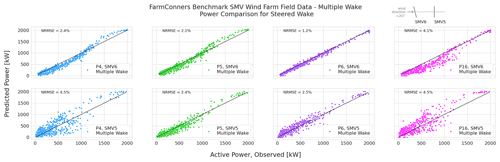

For the submitted time-series results from P4, P5, P6, and P16, the predicted and observed power values at the upstream and downstream turbines are compared in Fig. 12. The root-mean-square errors are normalized (NRMSE) by 2050 kW rated power of the turbines. For the upstream turbine, SMV6, with wake steering control (or yaw misalignment) of −13.3∘ mean anticlockwise, P4 and P16 are seen to underestimate the power production for lower wind speeds. On the other hand, P5 seems to overestimate the SMV6 turbine power for higher wind speeds, around the transition between Regions II and III. P6, however, is seen to have a very good agreement with the observed power at the controlled SMV6 turbine upstream, though potentially with a slight under-estimation.

Figure 12SMV wind farm (WF) field data, single wake under wake steering power comparison per participant. Upstream (top row) turbine power under wake steering control of −13.3∘ misalignment, downstream (bottom row) turbine power under the steered wake – field observations vs. participating model predictions. Representative layout with corresponding yaw control set point is illustrated at the upper right corner.

At the downstream turbine under a steered wake, SMV5, the variance around the power predictions is notably higher for the steady-state models, potentially driven by the wake-added turbulence. The underestimation trend by participants P4 and P16 continues at SMV5 power comparisons as well, although a lesser discrepancy is observed for P16 results.

As stated earlier, the calibration data set the participants were provided for the wind farm field blind tests is limited to normal operation conditions. The limited calibration data surely affect the performance of all the participating models. This impact is arguably the most visible for P4 and P5, where the same WFFC-oriented platform is utilized. Between P4 and P5, the difference in the comparison for both the upstream and downstream power predictions is expected to be driven by the prior calibration and the final selection of the parameters for the controlled periods. Specifically, the implemented yaw loss exponents n = 3 for P4 and n = 1.88 for P5 (see Table 6) are argued to be the main factor for the difference observed in the upstream power predictions, especially compared with the recent field calibration at the same site under WFFC, discussed in Simley et al. (2021) where wind-speed-dependent (or indirectly CT) values of n≈2.2–2.3 for wind speeds between 4 and 8 m s−1, n≈1.3–1.35 for 8–12 m s−1, and n≈0.36 for 12–14 m s−1 are reported. In that regard, Fig. 12 highlights the sensitivity of the widely adopted WFFC-oriented models to the employed parameters and the importance of comprehensive calibration data and process. It also shows the significance of clear parameter descriptions for overall reproducibility of the results.

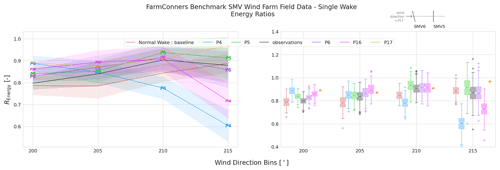

2.4.2 Binned quantities of interest: energy ratio and power gain

To analyse the effect of wake steering on the two-turbine wind farm (SMV6 as upstream, SMV5 as downstream), a similar methodology to that described in Fleming et al. (2019) is followed. Accordingly, both the observed power and the estimations by the participating models are distributed over ±0.5 m s−1 wind speed and ±2.5∘ wind direction bins. Per bin, the energy ratio, REnergy, is calculated via Eq. (2) with weighted summation, where N is the total number of wind speed bins per sector, ωi represents the weights per bin, is the mean of the total wind farm power per bin (either the normal operation/baseline power or power under wake steering WFFC) and for the single-wake case , and is the gross production averaged per bin, i.e. the power of the wind farm without the wake losses ( for single-wake case).

The weights per wind speed bin, ωi, aim to compensate for the non-equivalent number of samples within the “yaw misalignment” and “baseline” periods (see Fig. 11) in energy ratio estimation. Accordingly, they are assigned via the relative density of the samples within the respective bins. Therefore, the wake observed under normal operation (referred to as “Normal Wake : baseline”) and the gross production PRef have identical weights (both sampled under baseline period), where the observed and estimated wakes under WFFC have higher weights to compensate for a shorter yaw misalignment period in the data set. As an indication of uncertainty around the energy ratios, the standard deviation of the total power per wind speed bin is propagated, assuming the numerator and denominator of Eq. (2) are uncorrelated. Detailed description of the weighting strategy and the energy ratio calculation as well as the simplified uncertainty propagation can be found at the post-processing notebook published at the open-access FarmConners benchmark repository (Göçmen et al., 2021). It should be underlined that the resulting distribution of the model results considers only the variance in the time-series samples within the bin and is therefore simplistic and potentially conservative. A comprehensive analysis including input and model (parameter) uncertainties and their propagation is left as future work.

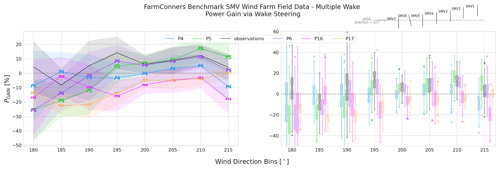

Figure 13 shows the energy ratio, REnergy, during the normal operation (or baseline) as well as under wake steering WFFC as observed on the field or estimated by the participating models (P4, P5, P6, P16, P17), per wind direction bin. Especially in the close-to-perpendicular wind sector, where , it can be seen that the steered wake is observed and estimated to be more energetic (i.e. higher REnergy), indicating a positive energy gain. The behaviour and the scale of the observations are in line with the recent field test results from the same SMV wind farm (Simley et al., 2021). For the participating models, the agreements are significantly better in the close sector. However, the variations notably increase at the wake border around 215∘. For the first wind sector centred around 200∘, all the models are seen to overestimate the energy ratios compared to the observations. The overall agreement becomes much better closer to the wake centre at the 205∘ bin, where P16 has a slight over-estimation. In line with the power scatter plots in Fig. 12, P4 notably underestimates the energy ratio for the remaining two sectors, where P5 and P6 have similar and overall very good agreement with the observations, and P16 has mostly good agreement except of the significant under-estimation around the wake border at 215∘. Note that for P17, where only the pre-binned quantities of interest were submitted, Fig. 13 includes only the mean REnergy. Based on the mean quantities, P17 is observed to slightly overestimate the energy ratios for almost all the sectors analysed.

Figure 13SMV WF field data, single wake under wake steering – energy ratio comparison under wake steering control with −13.3∘ upstream misalignment. Representative layout with corresponding yaw control set point is illustrated at the upper right corner.

The power gain observed at the field and estimated per participant in the blind test is then calculated following Eq. (3), where the energy ratio computed in Eq. (2) during normal operation, is subtracted from the energy ratio under wake steering flow control . The uncertainty around the power gain is quantified via propagating the uncertainties of and estimated in Eq. (2).

Figure 14 compares the power gain under wake steering WFFC observed at the SMV wind farm and estimated by the participating models in the blind test. The boxplots show that for the close wake sector, i.e. , a positive power gain with 13–14∘ yaw control at the upstream turbine has above 75 % likelihood. In fact, the likelihood of more than 5 % gain in power exceeds 50 % in the same wind sector. However, around the borders of the wake, for the bins centred at 200 and 215∘, loss of power is equally as likely as a potential gain, indicating the importance of uncertainties for the risk assessment of WFFC implementation, also as underlined in Hulsman et al. (2020). Observably, the participating model behaviours for the power gain estimations follow the discussions on REnergy for Fig. 13. However it should be noted that P17 power gain now has a variation around its estimation, driven from the standard deviation of the energy ratio for the normal operation, in Eq. (2). With that, the over-estimation trend is down-scaled, and a better agreement can be argued for larger sectors >200∘.

2.5 Multiple-wake results

For the multiple-wake case, the estimated and observed performance of the SMV6–SMV1 downstream turbines is investigated within a larger wind sector starting from 180∘ up to 215∘, so that effects of the wake steering at SMV6 can also be observed at the turbines further downstream of SMV5. Due to the imperfect alignment of the farm layout, it must be noted that this does not correspond to a multiple full wake effect; instead it is most probably a combination of overlapping partial wakes. Furthermore, for wind directions close to 180∘, the misaligned turbine SMV6 is in the wake of SMV7. Given the uncertainty in the evaluation data set, mainly driven by the layout of the wind farm, the multiple-wake results of the wind farm field data blind tests are presented in Appendix A.

2.6 Summary of the wind farm field data blind test

Although it is the key priority for advancing wind farm control technology (van Wingerden et al., 2020), the field test and validation for WFFC-oriented models are significantly challenging due to the stochasticity, non-stationarity, high variability, and overall uncertainty. Specifically for the FarmConners benchmark, the highlights of the participating model performance for the wind farm field data blind test can be summarized as below.

-

Similar models, disparate behaviour. In this blind test, several participants implemented similar models to resolve the wake behaviour behind a steered turbine (as listed in Table 3). However, even for the same framework utilized by P4 and P5, the results are seen to notably differ. This indicates high model sensitivity to the employed parameters and emphasizes the importance of the calibration procedure, as also analysed for another wind farm by van Beek et al. (2021). It also underlines the significance of clear methodology description and parameter listing for reproducible and credible estimations of the potential benefits of the technology.

-

Importance of the calibration data set. In the wind farm field data blind test, the calibration data were confined to the normal operation periods. This was mainly due to the limited availability of the controlled operation, which is typically the case for the majority of the operating wind farms. However, the blind test results show how crucial the information regarding the power loss at the controlled turbine(s) and basic downstream behaviour is to be able to customize the low-cost, control-oriented models under low observability of inflow conditions and turbine response.

-

A better wake steering implementation at the field. Given the high sensitivity of the parameters on the prediction of the gains observed, it can be concluded that the wake steering solution in practice would/should not be designed solely based on normal operation data. It would/should rather follow an iterative process in which a priori strategy can be developed and implemented based on normal operation tuning or standard, recommended, or off-the-shelf parameter values. After a certain period of data collected (e.g. a few months), the model parameters could be updated and a posteriori strategy (with a new set of optimal yaw control set points) can then be defined. Such a process could continue until a satisfactory agreement is reached between the model results and the observations.

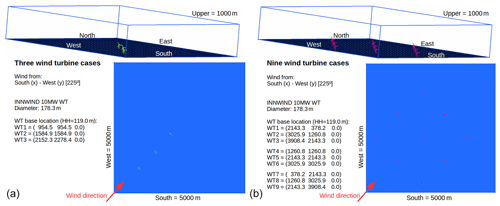

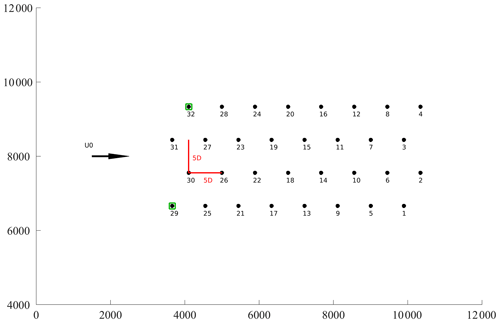

This blind test builds upon a set of high-fidelity simulations performed in the context of the European R&D project CL-Windcon (CL-Windcon, 2016). They were performed with NREL's open-source SOWFA simulation package (NREL, 2012), which is a set of computational fluid dynamics (CFD) solvers based on OpenFOAM (2013), boundary conditions, and turbine models represented through the OpenFAST simulation tool (Jonkman, 2017). The scenarios consist of two different layouts (see Fig. 15), for the 10 MW INNWIND.EU reference turbine (INNWIND.EU, 2013): (i) three turbines with a 3 × 1 configuration (3WT) and 5 D distance among turbines where the third turbine has 0.5 diameters (D) lateral displacement with respect to the flow, and (ii) nine turbines with a 3 × 3 configuration (9WT) and 7 D distance among the turbines. The numerical verification tests are presented in Doekemeijer et al. (2018), and further details on the simulation setup can be found in Gomez-Iradi et al. (2019) and Doekemeijer et al. (2019).

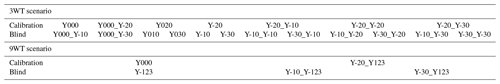

For the whole data set, combinations of three wind speeds, turbulence intensities, and roughness lengths were applied together with varied wind turbine control settings. However, for the specific blind test in FarmConners benchmark, an inflow corresponding to an average wind speed of 7.7 m s−1, turbulence intensity of 5.39 %, and roughness length of 0.001 m was selected (referred to as A4 in the original database CL-Windcon, 2019). The CL-Windcon LES blind test is among the most diverse and comprehensive in terms of the wake steering control strategies applied within the FarmConners benchmark. The yaw misalignment was varied in the range of ±30∘ for the first and/or the second row of turbines; see Table 7 for particular control settings among the 3WT and 9WT scenarios. The direction for the yaw convention, as well as the distribution of the control set points among the turbines, is illustrated per investigated case in the presentation of the results later in Sect 3.2 and 3.3.

Table 7Yaw misalignment control settings for the calibration and blind test for CL-Windcon LES cases. Yxxx: the downstream turbines are not misaligned where xxx [∘] indicates the yaw misalignment of the upstream turbine(s) (WT1 for 3WT scenario; WT1, WT4, and WT7 for 9WT scenario). Yxxx_Yyyy: upstream and the first downstream turbines are misaligned, where xxx [∘] and yyy [∘] indicate the yaw misalignment of the upstream and downstream turbines respectively. For 9WT scenario, xxx or yyy = −123 indicates −10, −20, and −30∘ yaw setting at turbines WT2, WT5, and WT8 respectively.

Targeted test cases explore a single full wake and multiple wakes under wake steering WFFC. Available data cover power production, hub-height, and/or rotor effective wind speeds at the turbines, as well as several structural loading variables, namely flap-wise root bending moment, total shaft bending moment, and total tower bottom bending moment. However, the load channels are excluded from the analysis in this study, and the participating models are evaluated based on the reported power production with and without WFFC.

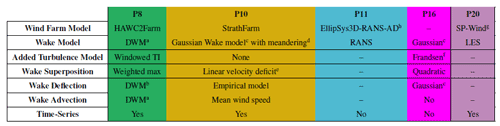

3.1 Participating models

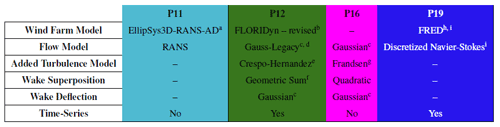

Within the FarmConners benchmark, the CL-Windcon LES blind test has had four participating models in total (IDs = P11, P12, P16, P19). Two steady-state and two (quasi-)dynamic models have been utilized for the exercise, covering a wide range of model fidelity. Table 8 lists their main characteristics for an easy comparison, especially for the lower-fidelity models. Further details of the implemented models are presented in the following sections.

Table 8Overview of the participating WFFC-oriented models, CL-Windcon LES blind test. a Sørensen (1995). b Becker et al. (2022a) and Becker et al. (2022b). c Bastankhah and Porté-Agel (2016). d Bastankhah and Porté-Agel (2014). e Crespo and Hernández (1996). f Shao et al. (2019). g Frandsen (2007) – IEC 2019 standard. h van den Broek (2021). i van den Broek and van Wingerden (2020) and van den Broek et al. (2022).

3.1.1 P11

P11 uses PyWakeEllipSys (DTU Wind Energy, 2021), which consists of the elliptic Reynolds-averaged Navier–Stokes (RANS) solver EllipSys3D (Sørensen, 1995). The numerical setup is similar to the one in Larsen et al. (2020), where the wake deflection was also studied. The turbines are modelled by Joukowsky actuator disks (no nacelle or tower is modelled), and the disc-averaged normal velocity is used to control each turbine using 1D momentum theory. The wind turbine data needed for the AD model, i.e. CT(UH,∞), CP(UH,∞), and TSR(UH,∞), are taken from the DTU 10 MW report by Bak et al. (2013).

Turbulence is modelled with the closure of van der Laan et al. (2015), and the inflow follows neutral atmospheric surface layer profiles. These profiles are prescribed to match the free-stream velocity and total turbulence intensity at hub height: UH,∞ = 7.7 m s−1 and IH,∞ = 5.4 % (the “A4” wind case of the CL-Windcon campaign used in the FarmConners benchmark).

3.1.2 P12

The parametric WFFC model used for this benchmark study by P12, also detailed in Becker et al. (2022a) and Becker et al. (2022b), will be referred to as FLORIDyn (FLOw Redirection and Induction Dynamics model). The central idea of FLORIDyn is to approximate the dynamic wake behaviour of wind turbines in a wind farm with low computational cost by piece-wise updating the steady-state flow field with a new steady-state description which fits the new states. This update from the precursor FLORIS model (see Doekemeijer et al. (2020)) is driven by observation points (OPs), which are created and updated at the rotor plane for each time step. They represent the influence of the turbine state travelling downstream. Within FLORIDyn, the steady-state wake is modelled via FLORIS (NREL, 2021), which is then propagated through the wind farm, instantly affecting turbines downstream. For instance, when the yaw angle of the turbine changes, the new generation of OPs will copy the new angle while old OPs still travel according to the previous angle. In the case of overlapping wakes, an OP travels into the wake of another turbine. It locates the closest upstream and downstream OPs from the foreign wake and interpolates their reduction factor at its location. The calculation of CT and CP is based on the lookup table generated via SOWFA (NREL, 2012) high-fidelity simulations for the reference turbine in the blind test. For the current benchmark study, the statistical properties of the wind field are matched (mean wind speed and turbulence intensity); however, no specific calibration to match to the CL-Windcon LES wake data was performed. Calibration using uncertainty quantification is intended to form part of a future publication.

3.1.3 P16

For the P16 results, the same in-house wake modelling tool as described in Sect. 2.2.4 is used. It consists of a Gaussian-based wake model (Bastankhah and Porté-Agel, 2016) with a quadratic single-wake superposition model. Based on the calibration data provided, the wake model parameters , and βd are also optimized with the SGA optimizer of the “pygmo” library (Biscani and Izzo, 2020) and the same loss function, i.e. the sum of the average quadratic differences between the calibration states power and simulated power at every turbine of the wind farm. However, the optimization procedure is different compared to the SMV wind farm field data blind test. Instead of using a single global wake model parameter for all turbines, here each turbine has independent wake model parameters which are determined by the optimizer. The power loss and the dependency of CT on the yaw angle are modelled by factors (cos Ψ)n, with the same values for n=1.88 as described in Sect. 2.2.4 and Eq. (1). For the power and thrust curves a lookup table that was derived from the BEM model of the 10 MW DTU reference turbine is used.

3.1.4 P19

The dynamic WFFC model used for this benchmark study by P19, currently under development (van den Broek, 2021), will be referred to as FRED (Framework for wind farm flow Regulation and Estimation with Dynamics). For the sake of brevity, a concise description is presented here, and interested readers may refer to van den Broek and van Wingerden (2020) and van den Broek et al. (2022). The model is based on Navier–Stokes equations that are discretized in time and a finite-element method that is used for spatial discretization with the Taylor–Hood element (Wieners, 2003). Dirichlet boundary conditions (Givoli and Keller, 1989) prescribe the inflow velocity. The inflow boundaries are dynamically chosen based on the wind direction. For example, for the current blind benchmark case where the wind flows from the south-west direction, the south and west boundaries are marked as inflow. The other boundaries are given Neumann conditions (Givoli and Keller, 1989), by default. The model is initialized with a uniform flow field given by initial velocity and a constant pressure. A generalized mixing length (Morgan et al., 1977) model is used to model the sub-grid-scale eddy viscosity. The wind turbine forcing on the flow is approximated using an actuator disc model. For the current benchmark study, the statistical properties of the wind field are matched (mean wind speed and turbulence intensity); however, no specific calibration to match to the CL-Windcon LES data was performed. Calibration is intended to form part of our future works.

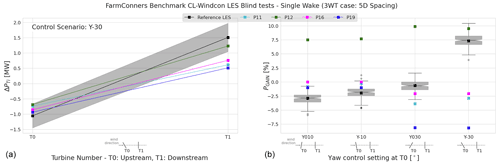

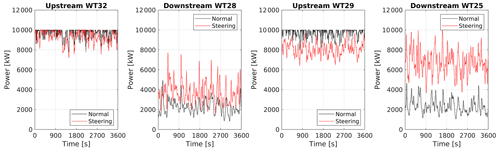

3.2 Single-wake results

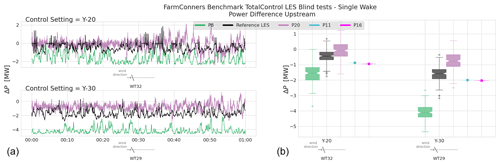

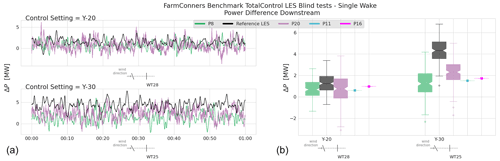

To have a generic comparison for both the single and multiple-wake results for two time series and two steady-state results submitted, exclusively the mean quantities of interests estimated by the participating models are presented in the CL-Windcon LES blind test results. Accordingly, the mean power per turbine, PTi, submitted by the participants under WFFC and normal operation are used to calculate the power difference per turbine, ΔPTi, and power gain, PGAIN, by Eqs. (4) and (5) respectively:

where P is the power and Ti is the turbine ID within the wind farm configuration (T0 for upstream, T1 for downstream in the single-wake case).

Figure 16 shows ΔPTi and PGAIN for a single wake with 5 D spacing where the upstream turbine, T0, is misaligned +10∘ (Y010), −10∘ (Y-10), +30∘ (Y030), and −30∘ (Y-30). For PGAIN in Fig. 16, the boxplots represent the distribution of the reference high-fidelity simulations at each control setting, where the mean PGAIN estimated by the participating models is illustrated on top. For ±10∘ misalignment at T0, CL-Windcon LES shows that the likelihood of power loss (up to more than 5 %) is higher than the gain for the investigated two-turbine configuration. This is relatively well captured by P11, P16, and P19, where P12 overestimates the potential of the control strategy. However, for larger upstream misalignment, the agreement between the participating models and the validation data set generally declines. For +30∘ steering at T0 (clockwise rotation), the low likelihood of the power gain is closely estimated by P16, and P11 and P19 indicate over-estimation of the wake losses, and the general trend of high-gain predictions from P12 continues. The asymmetry in the wake behaviour is significant when investigating the −30∘ steering set point, which is likely to be caused by wake rotation and/or wind veer combined with the upstream misalignment. This is, although less pronounced, also observable for ±10∘ and not represented by the participating models for either of the control settings. For the −30∘ upstream steering, the potential of the power gain exceeds 5 % in CL-Windcon LES results, which is relatively well captured by P12 and significantly underestimated by the other models. These rather pessimistic gains reported at −30∘ steering can be further analysed by ΔPTi in Fig. 16. There, it is seen that the upstream power loss is represented fairly well by all the participating models (within ±1 standard deviation bounds), but the wake losses behind a misaligned turbine are overestimated by the majority of the models, except for P12. This can potentially be explained by the less wake deflection produced by the models, as e.g. studied previously for P11 (Larsen et al., 2020). The same trend is visible in the other high-fidelity simulations within the benchmark as well, as can be seen in the TotalControl LES blind test in Sect. 4.2, for high degrees of upstream misalignment in P11 and P16 results.

Figure 16CL-Windcon LES blind tests, single wake under wake steering for the three-turbine configuration (3WT) with 5 D spacing. (a) Power difference (mean) in absolute values (MW) per upstream (T0) and downstream (T1) turbine, when T0 is −30∘ misaligned (Y-30). (b) Power gain (mean) for the two-turbine subset of the wind farm (T0 + T1). Boxplots represent the distribution of the reference CL-Windcon LES time series per control setting where T0 is steered +10∘ (Y010), −10∘ (Y-10), +30∘ (Y030), and −30∘ (Y-30). Representative layouts with corresponding yaw control settings are illustrated along the x axes.

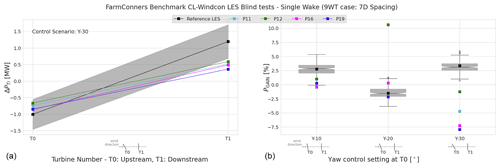

Figure 17 investigates ΔPTi and PGAIN for a single wake, this time for the 9WT scenario with 7 D spacing where the upstream turbine, T0 is misaligned −10∘ (Y-10), −20∘ (Y-20), and −30∘ (Y-30). It should be noted that the control settings presented here in the 9WT single-wake cases are the subset of the Y-123 settings under the blind tests reported in Table 7, based on each row of turbines in Fig. 15. PGAIN in Fig. 17 shows an interesting trend where −10 and −30∘ upstream misalignments result in positive power gain but −20∘ indicates a potential power loss for the investigated two-turbine configuration in the reference CL-Windcon LES results. Compared to 5 D spacing in Fig. 16, −10∘ upstream misalignment produces more power at the 7 D downstream turbine, hence the positive power gain which is slightly underestimated by the participating models. The agreement for −20∘; however is significantly better for the majority of the models, which could be due to the same upstream control setting in the calibration data set, though the downstream yaw setting(s) are different (i.e. Y-20_Y123 in Table 7). The upstream power loss due to misalignment is more than compensated for by the −30∘ yaw setting in CL-Windcon LES results, as also seen in ΔPTi behaviour. However the downstream power gain is significantly underestimated by all the models, as also observed and discussed for 5 D spacing in Fig. 16 as well as under similar upstream control settings applied in TotalControl LES in Sect. 4.2 where P11 and P16 also participated.

Figure 17CL-Windcon LES blind tests, single wake under wake steering for the nine-turbine configuration (9WT) with 7 D spacing. (a) Power difference (mean) in absolute values (MW) per upstream (T0) and downstream (T1) turbine, when T0 is −30∘ misaligned (Y-30). (b) Power gain (mean) for the two-turbine subset of the wind farm (T0 + T1). Boxplots represent the distribution of the reference CL-Windcon LES time series per control settings where T0 is misaligned −10∘ (Y-10), −20∘ (Y-20), and −30∘ (Y-30). Representative layouts with corresponding yaw control settings are illustrated along the x axes.

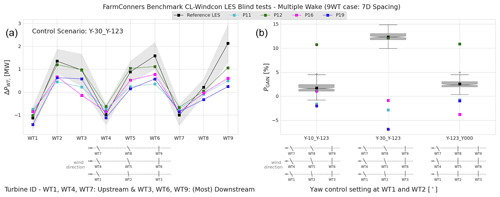

3.3 Multiple-wake results

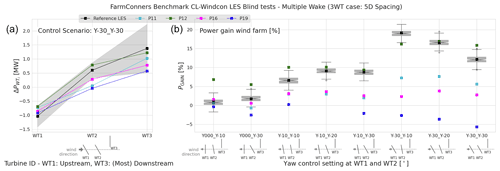

Similar to the single-wake results, the mean power estimated by the participating models is compared with the CL-Windcon LES blind test database for the multiple-wake cases. Accordingly, the power difference per turbine and the wind farm level power gain via Eqs. (4) and (5) are presented in Figs. 18 and 19. The turbine IDs for multiple-wake cases, however, are WT1, WT2, and WT3 for the three-turbine configuration and WT1, WT2, …, WT9 for the nine-turbine configuration. The representative layouts as well as the turbine-specific control settings within the investigated wind farm configuration are illustrated on the x axes of Figs. 18 and 19.

Figure 18CL-Windcon LES blind tests, multiple wake under wake steering for the three-turbine configuration (3WT) with 5 D spacing. (a) Power difference (mean) in absolute values (MW) per turbine, when WT1 and WT2 are both −30∘ misaligned (Y-30_Y-30). (b) Power gain (mean) per control setting in the three-turbine wind farm. Boxplots represent the distribution of the reference CL-Windcon LES time series per control setting listed in Table 7. Representative layouts with corresponding yaw control settings are illustrated along the x axes.

Figure 18 shows ΔPTi and PGAIN for three turbines with 5 D spacing (where WT3 is laterally 0.5 D apart) for several upstream and (first) downstream yaw control settings for the CL-Windcon blind tests listed in Table 7. For the investigated configuration, Fig. 18 indicates that the power gain is mainly driven by the control setting applied at the upstream turbine, WT1, where the misalignment of WT2 has a relatively lower impact. This is in line with other LES studies that investigate multi-turbine wake steering (e.g. Archer and Vasel-Be-Hagh, 2019). Especially with the lateral spacing of WT3, all the control cases where WT1, is misaligned indicate positive power gain up to more than 20 % in CL-Windcon LES runs. For all the participating models except P12, this trend is highly underestimated, and the agreement gets gradually worse with higher wake deflection. P12, however, estimates the behaviour relatively well, especially when WT2 is also misaligned. This can potentially be attributed to the high levels of wake deflection embedded in P12 model parameters. ΔPTi enables a closer look at the power difference at the individual turbine level for the highest degrees of control settings at WT1 and WT2, −30∘ each. There, similar to the single-wake analyses, it can be seen that the upstream losses observed in reference CL-Windcon LES at WT1 are relatively well represented by the participating models, but potential gain at the controlled downstream turbine (WT2) is underestimated by the majority. In addition to the under-representation of the wake deflection compared to the CL-Windcon LES, the difference in the power yaw loss exponent, n in Eq. (1), for the misaligned turbine in the wake can also play a role here, as demonstrated in Liew et al. (2020b). For the laterally spaced most downstream (WT3) turbine, the overall behaviour in the power performance is seemingly captured by all the participating models. However, significantly higher fluctuation in the expected power gain at WT3 should also be noted with approximately ±1 MW.

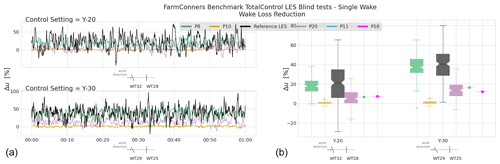

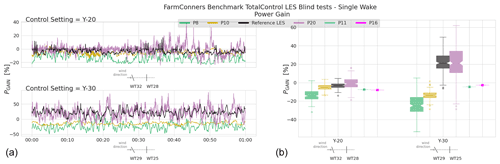

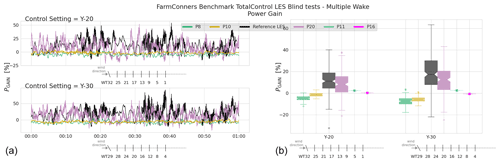

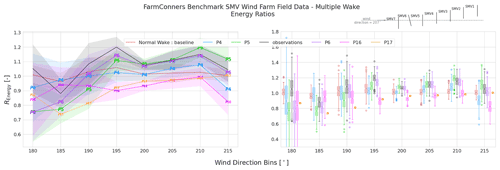

Figure 19CL-Windcon LES blind tests, multiple wake under wake steering for the nine-turbine configuration (9WT) with 7 D spacing. (a) Power difference (mean) in absolute values (MW) per turbine, for the control case Y-30_Y123 as shown in Table 7. (b) Power gain (mean) per control setting in the nine-turbine wind farm. Boxplots represent the distribution of the reference CL-Windcon LES time series per control setting listed in Table 7. Representative layouts with corresponding yaw control settings are illustrated along the x axes.