the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

Grand challenges in the design, manufacture, and operation of future wind turbine systems

Carlo L. Bottasso

Lance Manuel

Jonathan Naughton

Lucy Pao

Joshua Paquette

Amy Robertson

Michael Robinson

Shreyas Ananthan

Thanasis Barlas

Alessandro Bianchini

Henrik Bredmose

Sergio González Horcas

Jonathan Keller

Helge Aagaard Madsen

James Manwell

Patrick Moriarty

Stephen Nolet

Jennifer Rinker

Wind energy is foundational for achieving 100 % renewable electricity production, and significant innovation is required as the grid expands and accommodates hybrid plant systems, energy-intensive products such as fuels, and a transitioning transportation sector. The sizable investments required for wind power plant development and integration make the financial and operational risks of change very high in all applications but especially offshore. Dependence on a high level of modeling and simulation accuracy to mitigate risk and ensure operational performance is essential. Therefore, the modeling chain from the large-scale inflow down to the material microstructure, and all the steps in between, needs to predict how the wind turbine system will respond and perform to allow innovative solutions to enter commercial application. Critical unknowns in the design, manufacturing, and operability of future turbine and plant systems are articulated, and recommendations for research action are laid out.

This article focuses on the many unknowns that affect the ability to push the frontiers in the design of turbine and plant systems. Modern turbine rotors operate through the entire atmospheric boundary layer, outside the bounds of historic design assumptions, which requires reassessing design processes and approaches. Traditional aerodynamics and aeroelastic modeling approaches are pressing against the limits of applicability for the size and flexibility of future architectures and flow physics fundamentals. Offshore wind turbines have additional motion and hydrodynamic load drivers that are formidable modeling challenges. Uncertainty in turbine wakes complicates structural loading and energy production estimates, both around a single plant and for downstream plants, which requires innovation in plant operations and flow control to achieve full energy capture and load alleviation potential. Opportunities in co-design can bring controls upstream into design optimization if captured in design-level models of the physical phenomena. It is a research challenge to integrate improved materials into the manufacture of ever-larger components while maintaining quality and reducing cost. High-performance computing used in high-fidelity, physics-resolving simulations offer opportunities to improve design tools through artificial intelligence and machine learning, but even the high-fidelity tools are yet to be fully validated. Finally, key actions needed to continue the progress of wind energy technology toward even lower cost and greater functionality are recommended.

- Article

(18816 KB) - Full-text XML

- BibTeX

- EndNote

Wind energy has by many measures been a great success. The world now depends on over 5 % of its electricity supply from wind, and the installed capacity is about three-quarters of a terawatt (GWEC, 2021). At certain times and places the contribution is much larger; Denmark has exceeded 50 % of its electricity from wind on average, and the much larger grid demands of Germany topped 30 % from wind in the first half of 2020. The expectation is that the energy system needs to move away from fossil fuels to carbon-free sources quickly to respond to international climate change agreements. The only major carbon-free energy supply sources already ramped up and capable of providing the needed 10 TW or more of new generation within the next 2 decades are wind and solar. The Global Wind Energy Council (GWEC) notes that the current fast pace of wind energy deployment, 93 GW in 2021, needs to double to meet established net-zero carbon goals. Wind energy is in many ways already a fully developed technology, but current understanding will at best reproduce current products at larger scale and in greater numbers. A more solid, scientific basis is needed to feed the innovation that will be required of future wind turbines and plants in new environments, such as floating offshore, customized for low-resource sites on land, meeting additional grid services, and considering both social and environmental impacts. This article suggests that critical research on wind energy is yet to be done and lays out the gaps in understanding that must be addressed to move wind turbine technology forward to meet global demands. Figure 1 illustrates the scope of the issues that need to be addressed in a wind-turbine-focused research agenda that enables wind energy to supply its expected share of the carbon-free energy system of the future. This article provides the details of research on the turbine that could not be included in the highly condensed article in Science, which defined three areas of grand challenge: the atmosphere, the turbine, and the plant/grid (Veers et al., 2019). It also updates the work of the European Academy of Wind Energy (EAWE) in its foundational assessment of long-term research challenges given the emerging understanding of the issues over the last half-dozen years (van Kuik, et al., 2016). This new work is encouraged by the EAWE Publications Committee and is intended to assist the International Energy Agency (IEA) Wind Technology Collaboration Programme in generating a revised road map for critical wind energy research.

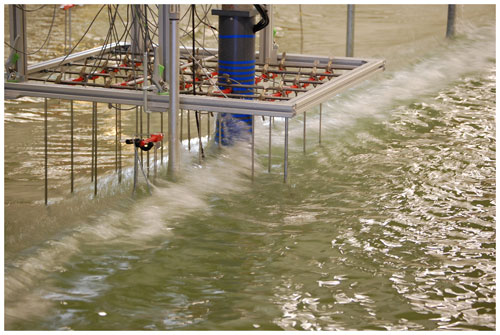

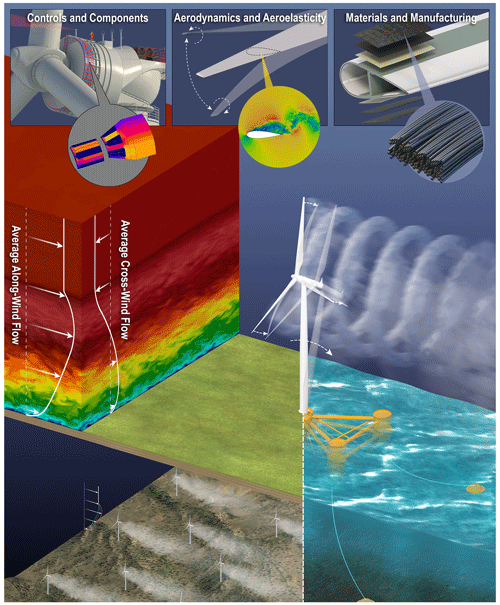

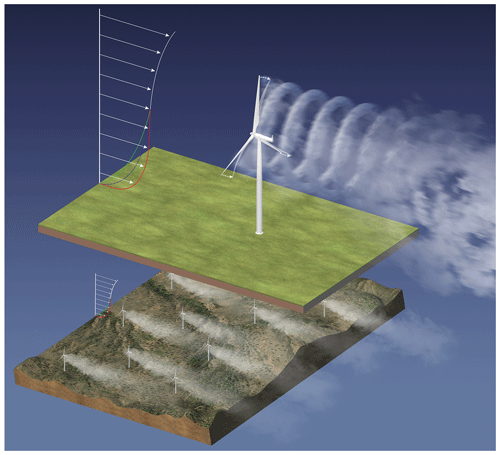

Figure 1Current wind turbines are so large their blades extend above the atmospheric surface layer. Their long, flexible blades interact dynamically with the complex inflow field. This complexity is enhanced in offshore applications when the turbine is installed on a floating support structure that is itself moving. Within a wind power plant, the flow is also disturbed by the wakes of other turbines. Advanced controls in combination with new sensors and innovative drivetrains (top left panel) will be integrated into a co-design-capable process. Aeroelastic simulation tools (top center panel) need to capture the larger scale, increased flexibility, and inflow complexity, often using high-fidelity simulations. Manufacturing processes will be expected to use new materials with increased strength and lower weight, with high quality at lengths over 100 m (top right panel). (Image credit: Besiki Kazaishvili, National Renewable Energy Laboratory – NREL.)

1.1 Background

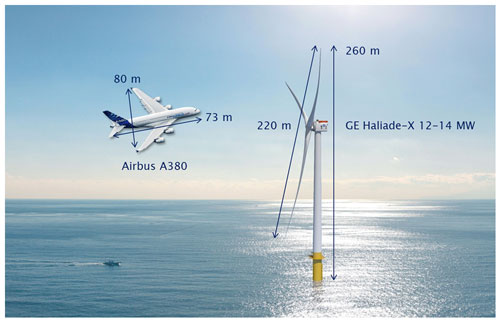

Between the 1980s and today, the size of utility-scale wind turbines increased by well over an order of magnitude, as shown in Fig. 2. Advanced designs, new materials, and the evolution of higher-fidelity modeling capabilities have led to less expensive and more operationally efficient wind turbines. Modern blades are 90 % lighter than blades from the 1980s if they were simply scaled up proportionately to the same length (Veers et al., 2019). This dramatic reduction is a prime example of how slender blades – with high-lift airfoils operating at higher tip speeds, stiffer materials, and optimized structural design – have revolutionized modern wind technology. Similar improvements in other components, such as variable-speed drives, coupled with advanced manufacturing processes, and smart operational controls have delivered higher-quality machines with better performance, greater resiliency, lower operation and maintenance (O&M) costs, and extended service life expectancy.

Figure 2Modern wind turbines are the largest rotating machines on Earth. It takes three A380s, the largest civil transport airplane in the world, to span the rotor diameter of a large offshore wind turbine. Different from airplanes, however, these machines are designed to operate in a fully autonomous manner in harsh environments, with minimum maintenance while ensuring high availability, accumulating about 100 million fatigue cycles throughout their 20-plus-year lifetimes. (Haliade-X rendering from https://www.ge.com/, last access: 19 June 2023; A380 rendering from https://www.airbus.com/en, last access: 19 June 2023.)

Modern wind power plants must operate at sites across a broad range of topographies and environments. Site-specific terrain and atmospheric conditions produce a diverse mix of inflow characteristics that make the design of lightweight wind turbines more complex. As turbines have drastically increased in size, the dynamics of the inflow relative to the size of the rotor, the key design driver, have gradually shifted. The characteristics of the atmospheric boundary layer (ABL), varying both temporally and spatially with weather-driven events, require predictive turbine modeling at a higher fidelity and resolution than currently available. Modern rotors span a significant portion of the ABL and experience extreme variability through every revolution. The inflow changes dramatically across the rotor diameter and varies in magnitude and characteristic (e.g., velocity, veer, sheer, turbulence structure), depending on local atmospheric conditions and the rotor location within the ABL. Perturbations from turbulence, veer, and sheer produce aeroelastic interactions with the increasingly flexible structures that surpass our experience base with current design tools. Wake interactions from multiple turbines within wind power plants further complicate turbulence experienced by the blades, as well as reduce overall power production. Moving offshore, and especially into deep waters, raises the bar even higher by adding inputs from waves and currents and coupling the turbine response with that of its massive, possibly floating, support structure. High-fidelity-modeling (HFM) and high-performance-computing (HPC) resources offer the opportunity to expand our current understanding and enable design tools to effectively explore innovative concepts computationally. But software capable of representing fundamental physics at a full-system level depends on code able to run on changing supercomputer architectures and validation of that software in full-scale field experiments.

The continuous market push for lower levelized cost of energy (LCOE) requires all components of the wind turbine system to be as light and cost-effective as possible while maintaining safety, performance, and reliability requirements. While blades and towers have increased structural capacity with both material and design advances, both have become lighter and dynamically softer, which brings them closer to coupling interactions and instability boundaries. Similarly, drivetrain technologies have become more torque-dense and reliable even as their size has increased, yet many design and manufacturing challenges remain. The tools and design assumptions used to create the successful, but costly, stiff and bulky systems of the past need to be validated with respect to these new design realities. Improved materials and manufacturing methods offer options that need to be proven at scale to get to market. New modeling and analysis approaches are needed to bring higher-fidelity capabilities that incorporate more physics, capture coupled integrated systems, and support both deterministic and probabilistic aspects of optimization into the design process. Experimental campaigns are required to validate these evolving capabilities before they can be trusted for design purposes. Finally, the design process itself needs to be examined to best leverage the improved understanding of the inflow, better characterize as-manufactured properties, and increase sophistication of computational simulation and machine-learning capabilities.

1.2 The goals of design

What are the goals of future wind energy technology? Answering this question is key to understanding the scientific advancements that are necessary and the challenges that lie ahead and need to be overcome.

A first and primary goal is the economic optimization of the process of generating electricity from wind. The most adopted economic figure of merit is LCOE, although other “value” functions are receiving increased attention in recent times (Veers et al., 2019; Canet et al., 2022). Wind LCOE has been making impressive strides in the last 20 years (Veers et al., 2019), and ensuring low, competitive electricity costs remains a key objective in the design and operation of wind turbines and wind power plants. In fact, wind energy is very different from aeronautical or automotive applications, for example, wherein there is always a customer interested in paying a premium price to fly a special mission (e.g., search and rescue, transport, military operations) or to drive a high-performance car. Wind energy “flies” a unique mission: generating low-cost, reliable, renewable energy. The problem is made even more complicated by the fact that value assumes various meanings for different stakeholders; for example, the optimal value for society might be different than the optimal value for an energy company. More generally, future efforts in economic optimization should consider the overall life cycle of the wind turbine. When this is done, better machines can be designed that include many other considerations beyond LCOE, such as the controllability of the wind power plant; the carbon-dioxide emissions generated during production, installation, and decommissioning; the recyclability of the wind turbine at the end of life; the reuse or repurposing of components; and the impact on the environment and the economy.

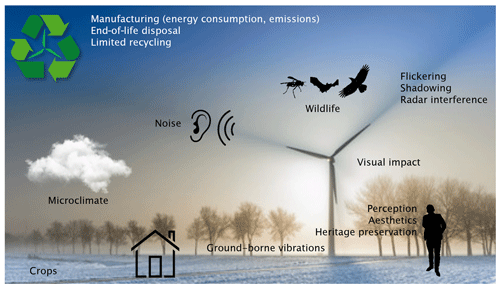

Considering the overall life cycle leads directly to a second goal, which is to minimize the negative impacts of wind energy technology. Although some effects on the environment are positive (e.g., the increased biodiversity observed in some offshore installations), it is clear that all energy technologies do generate some negative impacts. Wind is clearly no exception to this general rule (for example, see Fig. 3 for the onshore case) and can induce, in some cases, limited acceptance or even outright opposition from the public. It should be a primary goal of design – as the system-level integrator – to make wind energy a good neighbor. This means paying close attention to all of the many interactions and couplings of wind turbines with the extended environment (in its widest sense, including the natural and built environment) in which they operate.

Figure 3All sources of energy – including wind energy – or any human activity produces impacts on the natural and built environment, as shown here. Scientific knowledge and technology can mitigate these impacts, helping wind energy become a “good neighbor”. (Figure credits: Carlo Bottasso, Technical University of Munich; background photo: Rene Hartmann.)

In addition to better integration with the environment, a third goal of future wind energy technology is to seamlessly integrate into a new energy mix characterized by a prevalence of renewable sources. This goal is strictly related to the previously cited economic value; for example, with an abundance of wind capacity, electricity prices are inversely correlated with wind speed, and it pays to design turbines and plants capable of producing power in low-wind conditions (Madsen et al., 2020a) while limiting the maximum power in higher winds. It has been shown (Bolinger et al., 2020; Wiser et al., 2020; Swisher et al., 2022) that a low-specific-power (i.e., power divided by rotor swept area) system generally leads to the lowest LCOE and has the ancillary benefit of delivering power in times of low resource, therefore delivering a higher system value for the energy. Additionally, the integration of wind into the energy system of the future requires the ability to provide various services to the grid (Michalke and Hansen, 2014); to work in synergy with storage systems as well as renewable and non-renewable energy sources; or to use low-cost or surplus electricity for various production and reconversion pathways, often referred to as Power-to-X (Erdem, 2021).

Finally, a fourth goal is to shorten the design cycle, reducing costs and enabling faster adoption of new products to changing needs and requirements. As witnessed in similar engineering fields, the key enabler of shorter times to market is simulation technology through numerical prototyping. With general, comprehensive, robust, and reliable validated simulation tools, a closer match between design predictions and actual field behavior can be achieved, leading to fewer prototypes and posteriori fixes. Simulation also enables customization (i.e., the adaptation of generic design solutions to site-specific conditions) and the evaluation of design innovations that cannot be fielded until it is known that they have a high probability of success. Over time, an improved command of simulation technology also leads to greater confidence – with a reduced need to rely on safety factors to hedge against uncertainties – minimal failures, higher safety, and increased availability. In turn, this spurs a virtuous cycle that lowers financing and insurance costs and reduces liability, with obvious positive economic implications.

1.3 A guide to this article

This article is organized as follows. Section 2 is meant to serve as an effective executive summary, listing the critical challenges related to enhancing the cost-effectiveness and productivity of wind turbine systems. Sections 3–9 explain the scientific gaps in knowledge in each topic area and how those uncertainties are holding back progress. The topic areas are

-

Sect. 3. Inflow and design criteria

-

Sect. 4. Control and co-design

-

Sect. 5. Aerodynamics and aeroelasticity

-

Sect. 6. Wakes

-

Sect. 7. Offshore wind technology

-

Sect. 8. Manufacturing and materials

-

Sect. 9. High-fidelity modeling, high-performance computing, and validation.

Section 10 provides a list of high-level, major research initiatives that address critical gaps and provide the basis for the continued advance of wind turbine science and technology. Readers may focus on just those sections that most interest them to understand individual research needs more fully. The recommendations should be read by all because they represent suggested investment in research that will help unlock the full potential of wind energy to meet the demands of the future energy system.

1.4 Comment on scope

There has been a great deal of interest in breaking out of the current dominant architecture of wind turbines (e.g., horizontal axis of rotation, three blades, upwind, pitch controlled, variable speed) and exploring the opportunities provided by innovative systems, such as airborne wind, vertical axis, or even modestly adjusting the paradigm to operate downwind or with two blades. There is good reason to expect that substantial advantages may be available, as articulated by Watson et al. (2019). Exploring these innovative options will certainly bring their own challenges. This article is built on a synthesis of the literature to date and aims to build a clear picture of the critical research for the advancement of wind energy systems in general. The literature is dominated by what has been learned in attempting to engineer the current architecture and therefore is a rich source of what needs to be done. Therefore, this article has a natural emphasis on the difficulties uncovered in this long path to wind turbines that now dominate the market. However, both innovations in the current architecture and exploration of novel approaches will benefit from the closing of these critical research gaps.

As noted earlier, design is an exercise that necessarily encompasses a wide range of topics, involving engineering, environmental, and social considerations. However, to simplify this article and keep the discussion to a manageable length, the topic of social science and the intersection of design with environmental considerations are left to other studies in this series. This article will focus on the mechanical aspects of the wind turbine, its interaction with the atmosphere and sometimes the ocean, and the critical issues that arise from that perspective.

There are at least four key goals that must be a part of future wind turbine technology development. The first goal is economic optimization, which requires focused attention on driving down LCOE and increasing economic value, including decisions related to reuse, repurposing, decommissioning, etc. – all stages in holistic life cycle assessment. Second, the design process must consider the impact that wind energy development will have on the environment and maximize its value to the community. This requires that we minimize the negative impacts of wind energy technology and seek good neighbor status for wind interactions with the natural and built environments. A third goal is achieving seamless and economic integration with other energy generation sources and storage systems. Such integration requires optimized use of the wind resource with tailored specific-power considerations in low- versus high-wind-resource regions. The fourth goal is shortening the design cycle, which reduces costs and speeds up the adoption of new products to meet changing demands. Accurate, user-friendly simulation capabilities enable rapid design-option evaluation and could also lead to reduced reliance on overly conservative safety factors, thus increasing safety while reducing costs associated with insurance, liability, and failures.

Each increment in wind turbine growth has carefully avoided straying too far from known territory and has relied on safety margins that have been sufficient up to this point. However, turbine sizes have gradually moved outside the design basis while design practice continues as though this change has a negligible effect. High safety factors have kept us safe, but continuously removing cost and weight pushes safety margins down. As we try to customize designs for the specific conditions of each application, unknowns increase and the science gaps expand. Thus, the large and flexible turbines entering the market today have pushed into territory where there are significant unknowns. Because of the size, complexity, and cost pressures, many aspects of wind turbine design innovation are stifled by uncertainties, as articulated in Sects. 3–9 of this article and summarized here. Substantial opportunities for system improvement depend on resolving these issues.

2.1 Inflow and design criteria

The design process, as understood and practiced by the industry, is defined by a consensus standard intended to ensure a high level of product reliability. The rapid evolution of wind turbines to unprecedented size and new applications, such as the use of floating platforms offshore or oversized rotors on land, brings into question some of the historical design requirements. Because the current approach has resulted in reliable products, there may be understandable reluctance to change. However, ongoing market acceleration to create a carbon-free electricity system requires custom, rapid design optimization for continuous cost reduction. The design criteria must be able to accommodate these additional dimensions and bespoke applications.

Wind turbines now extend beyond the top of the atmospheric surface layer and experience inflow characteristics never encountered by smaller machines. Atmospheric flow phenomena at these scales are as diverse and complex as the local driving weather conditions. Extreme and previously unheeded conditions including hurricanes, tornadoes, microbursts, nocturnal and marine jet flows, and gravity waves must also be considered. Accurate modeling of the ABL state, including detailed inflow characteristics and extreme atmospheric events, is critical for designing the individual wind turbine, as well as the operational control of both turbines and integrated wind plant systems. The exact nature of atmospheric turbulence is not well-characterized at the length scales and resonant frequencies of the modern wind turbine structure. Turbulence at these scales (ranging from hundreds of meters down to just a few meters) is known to be non-Gaussian, non-stationary, and nonhomogeneous, whereas design criteria are based on conditions that are Gaussian, stationary, and homogeneous. The ABL stable–neutral–unstable transition cycle and corresponding change in the veer, shear, and turbulence (frequency content and coherence) all have fundamental impacts on design loading that need to be incorporated in modeling tools and design standards.

The current design standards often fail to capture the emerging understanding of the underlying physics driving modern designs. For example, inflow turbulence models incorporate simplified three-dimensional turbulence characteristics that are not intended to match the actual conditions but to serve as an envelope above the worst cases and thus provide a natural level of conservatism. Often, the design requirements simplify the critical physics that represent particular operating environments (e.g., marine boundary layer, complex terrain). Meanwhile, the ability of modern computational tools to simulate specific atmospheric dynamics and configuration changes has improved to where many of these simplifications may not be necessary. As a result, design criteria must evolve to include more of the relevant physics driving modern architectures and anticipate future requirements posed by unique operating environments.

In parallel with seeking a better understanding of the inflow environment, it is also important that the design process intrinsically accounts for and integrates the role of manufacturing, materials, and implied capacity of components and structures. Such considerations must reflect probabilistic realities in the evaluation of ultimate and fatigue limit states, in aerostructural loading assessments, and in deflections of long and flexible blades. Life cycle reliability of future wind turbines can also adapt successful practices from other industries, such as aerospace and automotive, where reliability-centered maintenance programs seek to limit costs and downtime while maximizing safety and other benefits. A future wind turbine probabilistic design paradigm would expand current design standards to include inflow parameters beyond mean wind speed and turbulence. Probabilistic considerations for capacity, even including operational data, might even allow for a reliability-centered maintenance program.

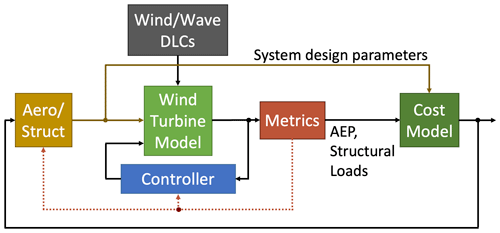

2.2 Control and co-design

Historically, wind turbine control has focused on the performance and survivability of an individual turbine. A fundamental change in design philosophy from individual turbines to multi-turbine wind plants operating as an integrated system has expanded the role and emphasis of control. As a result, highly flexible wind turbine control strategies are rapidly evolving. Advanced individual control systems are moving toward and/or adopting feedforward paradigms that monitor and “fly” rotors in response to changing inflow conditions (wind and/or waves in the case of floating offshore wind). The objective is to observe and respond to incoming flow to optimize the turbine control for in situ operating conditions. Challenges in control include probabilistic load control, where controllers are designed to account for uncertainties in the inflow as well as manufacturing variabilities. Another area requiring more development and analysis is that of fault-tolerant operational control that can detect and accommodate faults in a graceful manner through physical and algorithmic redundancies. The ultimate goal is for the control basis and objectives to be able to be programmed and altered in real time, thereby remaining responsive to changes in resource, market, O&M, and operational longevity, as required. Further, as wind turbines are all digitally controlled, there is a need to ensure cyber-physically secure operation of wind turbines.

Wind plant control is adopting turbine-to-turbine situational awareness to actively adapt yaw and pitch in ways that alter wake interaction and maximize plant performance. By selectively lowering the potential performance of a few turbines upstream, the total plant production, O&M cost, and system longevity can be improved. No longer must a turbine simply respond to the inflow resource. Instead, the wind plant system responds temporally and spatially to the inflow environment, interacts with the wind resource, and maximizes performance based on system performance optimization and control objectives. All of this, however, depends on accurate models of how wakes impact power performance and structural loading. Further work is also needed to develop wind farm site-specific and even turbine-pad-specific and power-performance-optimized controls that enable adaptive performance optimization in a volatile energy market.

Grid interconnect control is evolving to facilitate the grid of the future where up to 80 % of the electricity generated could be from wind and solar. In contrast to traditional power resources (e.g., coal, gas, nuclear, hydropower) that are connected to the power grid through large spinning synchronous electromechanical machines, renewable generation resources such as wind and solar are generally connected to the power system through power electronic inverters. Major power grid interconnections in many regions around the world are becoming hybrid power systems, comprising both traditional synchronous electromechanical-based resources as well as a noticeable and increasing fraction of inverter-based resources. While inverter controls today are predominantly grid-following, future power systems will involve a mix of inverter-based resources with both grid-following and grid-forming control capabilities. Grid-following inverters have limited capabilities and must receive voltage and frequency signals from external resources, whereas grid-forming inverters provide functionalities that are traditionally provided by generating resources with synchronous machines (Lin et al., 2020). Grid-forming inverters will be necessary for the stable operation of the bulk power grid with large amounts of wind and solar generation, and ongoing assessments of system performance along with the development of grid-forming controllers will also be needed (Lin et al., 2020). How both grid-following and grid-forming inverter control performance affect structural responses in wind turbines will also need to be carefully evaluated. As the grid interconnection demands expand, integrated control strategies from the individual turbine through the integrated wind plant are needed to accommodate ancillary services, curtailment, and reactive power responsiveness. The communication strategy, control paradigms, and integrated control architectures are rapidly developing to meet the future needs of integrating large amounts of wind energy into the grid system. Further, the much higher bandwidths (kHz vs. Hz) of the electromechanical and power electronic subsystems needed for integration and hardware control must evolve to guarantee high reliability and resilience.

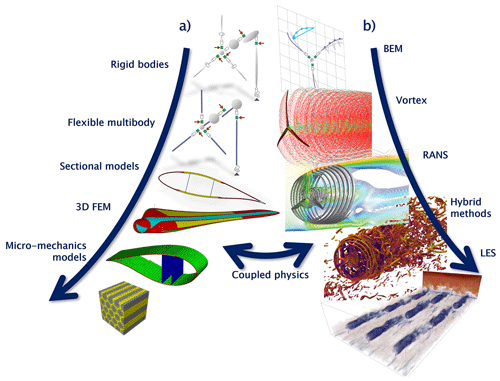

2.3 Aerodynamics and aeroelasticity

The significant blade flexibility of larger modern turbines calls into question many of the design assumptions and well-established performance characteristics of smaller and stiffer platforms. Blade dynamic motion and coupled aerodynamic response require comprehensive aeroelastic system design and assessment. Stability and damping criteria, if exceeded during nominal or extreme event operation, can drive nonlinear conditions that put the machine at risk and limit operability. Softer and more efficient designs are moving closer to stability boundaries, wherein aeroelastic couplings can induce catastrophic structural failure or reduce life expectancy. The integrated dynamics of such structural design strategies require more holistic systems analysis and modeling methods, capturing both the flow physics and the nonlinear dynamic response.

Classical aeroelastic design approaches assume “linear” deflections and small perturbations, thereby permitting two-dimensional (2D) simplifications of complex three-dimensional (3D) rotor flow and blade motion. Wind turbine blade performance is gleaned from simplified blade element momentum and lifting-line theory. Unfortunately, the flexibility of modern blades and the use of 3D flow control devices (e.g., vortex generators) call into question the assumptions of linear deformation, small perturbation, and 2D flow behavior. Further, the operating Reynolds numbers far exceed conventional wind tunnel test capabilities available worldwide, making validation of expected performance critical, especially for those conditions (e.g., post-stall angles of attack, dynamic stall, etc.) where computational fluid dynamics show the largest uncertainties. Hence, among other complexities, the airfoil properties and performance sensitivity to blade surface erosion, deterioration, and fouling cannot be validated. Greater margins of safety must be used in the integrated design of a wind turbine to account for a lack of understanding and an oversimplification in assumptions about dynamics, blade performance, and loads, but there is great uncertainty in exactly what these margins need to be.

Blade and tower flexibility introduces aerodynamic instability considerations that may now be considered principal design constraints in flexible architectures. Dynamically soft systems and 3D flow separation phenomena occurring at high Reynolds numbers make existing low- and mid-fidelity modeling and analysis methods incapable of capturing the critical physics and integrated system dynamics. Some examples include

-

Bend–twist blade coupling, flutter from lower torsional stiffness, instability modes involving combined edgewise and flapwise mode shapes, and blade dynamic stall, which introduce additional design model uncertainty.

-

Stall-induced vibration (SIV), which is an instability occurring when the motion of a blade, oscillating at a structural frequency, drives the incident flow angle beyond static stall, resulting in negative damping.

-

Vortex-induced vibration (VIV), which is a coupled phenomenon that may appear during separated flow. Sustained vibrations are expected when the frequencies of the shed vortices are in the vicinity of one of the structural frequencies. At different shedding frequencies, VIV can be experienced by wind turbine blades, towers, or nacelles.

The continuous operation of a wind turbine blade within the lower part of the ABL causes an unsteady inflow to a blade section and a complicated, unsteady aerodynamic response. In particular, the fact that the outer blade continuously traverses heights from 25 to 250 m of the ABL can cause significant and even extreme variations in the incoming turbulence characteristics. Three-dimensional flow effects diminish the accuracy of 2D polars. Even over one single rotor revolution, the local turbulent inflow to a blade section can undergo significant changes (Schaffarczyk et al., 2016; Özçakmak et al., 2020; Madsen et al., 2019a). The resulting large disturbances can cause abrupt transitions in otherwise smoothly developing boundary layers, with not yet fully understood consequences (Morkovin, 1985).

Aeroacoustic noise, which depends on blade tip speed raised to the fifth power, can restrict siting options because of the need to set back turbines from residences. Attempting to lower acoustic emissions can put constraints on the operating envelope that limit the options for low-wind-speed rotors on tall towers. The design consequence of restricting tip speed for acoustic reasons is a lower generator speed, a higher shaft torque, and an overall increase in drivetrain mass. Aerodynamic mechanisms that lower the acoustic emissions and facilitate higher tip velocities associated with faster rotor rotation are highly desirable (assuming blade leading-edge erosion can be managed). In fact, they would significantly lower tower-top mass and correspondingly reduce supporting tower and foundation stiffness requirements, thereby significantly lowering the total mass and system cost.

2.4 Wakes

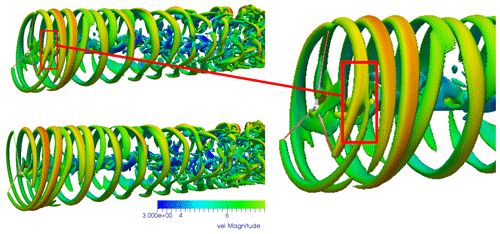

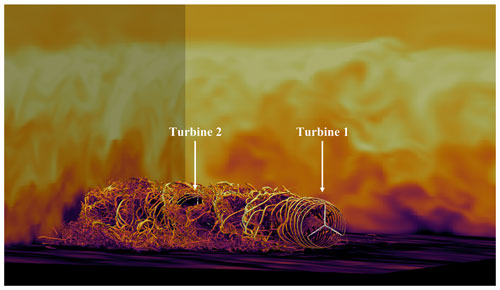

Wind turbine wakes within large wind power plants impinge on the downwind turbines in complex and poorly understood ways that increase loads, reduce operational life expectancy, and limit energy capture. On a macro scale, the combined wake structure from an entire wind plant can persist over tens of kilometers (especially offshore) and significantly impact the performance of wind plants operating downstream. Wake flow structure and meandering characteristics have a strong synergistic relationship to rotor design and the atmospheric conditions in which they develop and propagate downstream. Depending on spatially and temporally varying local conditions, turbine size, and height-to-diameter ratio, shed wake vorticity interactions can have strong adverse impacts downwind and represent a significant turbulence enhancement that impacts total load, machine life, production capacity, and even potential changes to the local microclimatology.

Industry models of wind plant–atmosphere interactions are highly uncertain, necessitating field campaigns to gather more detailed observations to achieve a deeper fundamental understanding of wind flows and validate industry and research-grade models. With improved understanding, the wind industry will be able to better design wind plant layouts and operational strategies to reduce overall wake losses and also help improve machine reliability through better management of turbulence within wind farms. A new generation of instrumentation to enable higher-fidelity observations of wind farm flow fields should also be developed.

2.5 Offshore wind technology

Offshore wind turbine systems need to operate in extremely harsh conditions. These massive, yet dynamically “soft” turbine structures, which are excited by strongly coupled aerodynamic and hydrodynamic forces, push the boundaries of our physical understanding and ability to adequately predict turbine response. Both shallow- and deep-water architectures are subjected to hydrodynamic wave and current loading, wake dynamics, and unique inflow characteristics (e.g., veer, sheer, turbulence, marine jets) of marine boundary layers. Designs are driven by both ultimate and fatigue loading and require a thorough understanding of the wind and wave characteristics, their interactions, and how to accurately capture their collective influence on these complex, dynamic systems.

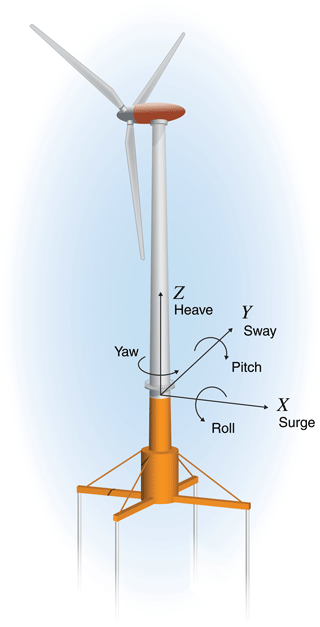

Offshore wind architectures are evolving along two pathways determined by water depth. Shallow-water designs may look similar to land-based systems, in which the tower is simply extended and piled into the seafloor. But as the water depth increases, and if the seabed conditions make piling difficult, more advanced designs may be needed. Research and development are focused on reducing the cost of the subsurface support structure, installation, and maintenance. In contrast, floating offshore wind turbine architectures are still evolving, and innovative designs are being imagined that transcend any existing floating structures in the water today. The full 6-degree-of-freedom floating platform motion exacerbates dynamic system coupling and stability concerns. As a result, research and development are focused on integrated system design, floating platform architectures, mooring and anchoring strategies, and advanced control to manage system dynamics. Moreover, the possibility of exploiting deep waters will give access to new sea basins, where wind speed distributions can be different from those exploited so far in offshore sites, opening possibilities for customizing the aeroelastic design of the rotors. Less traditional wind turbines, including downwind geometries and two-bladed rotors, could also re-emerge as design solutions for floating systems because of the increased benefits of reduced weight and tower-top loads on design costs.

Design simulation capabilities must capture the appropriate physics to compute transient system response at computational speeds that support probabilistic analyses across a range of parametric design requirements. An efficient design process for such coupled dynamic systems, driven by a multidimensional set of stochastic loading inputs, requires a multi-fidelity set of design tools. A new class of high-fidelity computational capabilities based on first principles and limited modeling assumptions offers a valuable means by which these tools can be made more accurate and validated for situations where measurements are impossible.

2.6 Manufacturing and materials

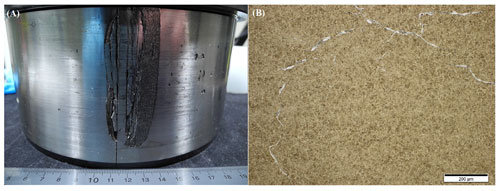

Modern wind turbine blades use hybrid composite structures to improve performance, reliability, and longevity and to reduce total mass, thereby lowering LCOE. Composite materials are manufactured in massive, single-shot molds, requiring consistent high quality over 100 m of continuous material, at less than 1/10 the cost per kilogram of typical aerospace materials. The principal blade load-bearing component is a carbon, glass, or hybrid composite spar cap that transfers the aerodynamic load to the rotor hub. Carbon fiber is often used because of its superior strength and stiffness properties that mitigate blade deflection with reduced mass. Glass fiber is used in the blade skin and leading and trailing edges to both transfer the aerodynamic load to the spar cap and provide buckling strength and toughness. Concern over future constraints that may be imposed by recyclability requirements are encouraging research to examine alternative materials, including thermoplastics and more exotic resin formulations that maintain the needed composite material properties.

Although the reliability of major components has improved, challenges remain and are an ongoing concern. Further, as the size and weight of these components increase and turbines are deployed offshore, consequent transportation and installation logistics and maintenance difficulties arise. Similarly, verification of large components by traditional testing techniques is becoming lengthy and costly, but verification of smaller parts through testing or verification by simulation, sometimes called numerical prototyping, holds promise for reducing costs and cycle time.

Generators often use permanent magnets made with rare-earth elements, which will be in increasing demand across many industries and applications. Therefore, significant investments are needed to overcome the weight and material availability constraints on existing permanent-magnet-generator architectures, such as by developing superconducting generators or other alternatives including magnet reuse and recycling.

Current design adequacy calculations do not incorporate the results of inspections performed either at the factory or in the field. Structural capacity that is based on the smallest detectable flaw and subsequent flaw growth hold the possibility of both enhanced safety and optimal material use. Probabilistic design methods that can directly incorporate inspection and repair of wind turbines during operation have the potential to both decrease component cost and improve reliability.

Increasing numbers of merchant market power plants will require greater knowledge of the current damage state of wind turbine components and the expected increase in damage during an operational period to be able to evaluate the economics of plant operation. Thus, improvements in inspection and structural health monitoring are needed, as is fundamental research, to define a better basis for assessing the progressive damage in components.

2.7 High-fidelity modeling, high-performance computing, and validation

Simulations using HPC of the fundamental fluid–structure interaction using HFM can capture the relevant turbine and plant physics but come at a substantial computational cost. Advanced computational methods are not readily applicable to design, which requires numerous simulations to represent the stochastic nature of the inflow. On the other hand, design tools using more simplified methods can be inherently conservative and more costly and must be accompanied by safety factors to account for modeling, operational, and physical uncertainties. As noted in the section on aerodynamics and aeroelasticity (Sect. 5), the increasing uncertainty associated with the accuracy of past or conventional assumptions raises many questions about the appropriateness of historical safety factors. Given the diverse range of uncertainty sources in flow physics characterizations and integrated system dynamics, the extent to which modern, highly flexible designs can be based on simplified physics, and on empirically derived models and approaches, is uncertain.

Future design models will need to couple the fidelity and physics embedded in advanced HFM at computational speeds that allow for the multiple iterations achieved with today's low- and mid-fidelity models. Artificial intelligence (AI) and machine learning (ML) offer a means by which high-fidelity data from HFM physics-based models are used in training lower-order models for turbine and plant design. Although early in the development stage, these tools have the potential to capture the relevant physics and fidelity needed to simulate integrated complex systems at computational speeds that are equivalent to lower-fidelity empirical design models.

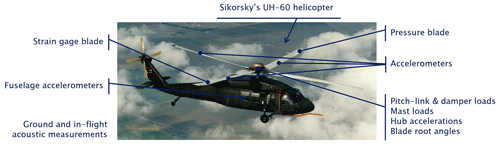

All models require verification and validation through laboratory and field experiments. The goal of numerical prototyping depends on models that are validated and predictive. Data and the results from analytical models both come with varying levels of uncertainty that must be quantified such that the range of applicability of the model can be established. The data required to validate high-fidelity models are both difficult to obtain (if even feasible to collect) and represent a significant monetary investment. Data assimilation methods also need to improve for these highly complex experiments to inform the equally complex computational models. Most system performance data that exist are proprietary and held as protected intellectual property by individual companies. The future advancement of modern flexible turbine architectures and advanced wind plant systems will require publicly available, high-fidelity experimental data that are obtained and distributed through public collaborations and consortia.

2.8 How is this holding back progress?

The path forward for designing and operating these massive, manufactured structures is system design based on validated and therefore trustworthy numerical models. Great strides have been made over the past few decades using simple yet effective models of atmospheric turbulence, rotor aerodynamics and elasticity, advances in composite manufacturing, and system optimization. The design tools that have been honed over time depend on these simplifications. Yet, wind energy technology has reached the point at which each of the simplifications is beginning to exceed the range of conditions for which the assumptions were created in the first place. The scientific uncertainty outside the range of previous experience limits the ability to innovate. Risk aversion is a fact of life – each wind turbine now manufactured is a multi-million-dollar product and each power plant can be a multi-billion-dollar investment. New technologies, materials, or operating paradigms require validated computational models to analyze the full-system implications of component-level decisions. The next strides forward in wind energy technology will depend on a revolution in our scientific understanding of these complex and multi-faceted systems.

The multitude of design requirements and coupled effects in a wind turbine system invariably pull the system in different – often opposing – directions. It is the role of design to bring all of these aspects together, providing the crucial, system-wide point of view wherein all compromises and trade-offs among the many internal and external effects are considered. It is the design process that must find an optimal solution between low capital cost, high productivity, long-term reliability, and mitigation of environmental and social impacts. It is also the role of design to ensure that the solution satisfies all necessary constraints. In fact, design constraints extend beyond the domains of aerodynamics, structures, and controls to include extra requirements linked to production, logistics, operation, maintenance, disposal, recycling, and so on.

Design is an iterative process that starts with the specification of high-level goals and requirements all the way to the detailed definition of a system. In all advanced engineering fields – and wind energy is no exception – this process is fundamentally linked to the ability to simulate the system. In fact, without simulations, the design process is limited to build and test (i.e., trial and error), which is lengthy, expensive, potentially unsafe, and in general unable to extensively scan the solution space or find an optimal design. Simulation builds on three pillars: (1) science-based mathematical models of all relevant physical effects and their mutual interactions, (2) a holistic approach to couple the numerical methods that solve the models using digital computations to produce predictions, and (3) experimental data that are used for quantifying the accuracy of those predictions with respect to reality and possibly tuning the models. Hence, simulation technology, with its three pillars, is the key enabler of the design of current and future wind energy systems.

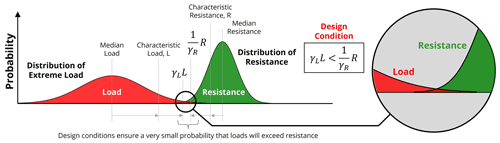

Figure 4Schematic of the design process. Characteristic values of loads are taken from the upper tail of the distribution, typically associated with a 50-year return period for an intended 20-year design life. Strength values are taken from the lower tail of the strength distribution at a select level of statistically defined minimum material strength. A margin of safety is defined to ensure that the probability of an uncertain load exceeding the uncertain resistance (strength) is very small. (Figure credit: Lance Manuel, University of Texas at Austin.)

In the wind energy field, design is also a structured process based on standards (IEC, 2019). Standards play the crucial role of distilling the current state of the art into procedures that can be used by industry, bridging science with engineering practice. Design standards also formulate all the normal, extreme, and emergency conditions that a turbine may encounter over its entire lifetime, typically 20–30 years (Barone et al., 2012; Manuel et al., 2013). These conditions ultimately yield the fatigue and extreme loads that the machine should sustain, which may require thousands of transient aeroelastic simulations. Clearly, this has a very large impact on the fidelity of the models that can be used for design. Being at the heart of design and representing a central element of safety, standards are of crucial importance going into the future. First, they should evolve to accommodate the new conditions that extremely large turbines will encounter. Second, standards should evolve as knowledge and analysis methods improve. This evolution is already happening to some extent, as researchers examine replacing deterministic “equivalent” conditions intended to capture extreme events with more probabilistic-based methods (Moriarty et al., 2003; Sørensen and Toft, 2010). Further progress in this realm is important to ensure safety while avoiding unnecessary conservatism.

3.1 Classical design approach

The classical approach to design uses a process that considers the uncertainties in both the load (L) and the strength or resistance (R), as illustrated in Fig. 4. It uses “characteristic” loads and resistances, accompanied with calibrated safety factors, to ensure that the probability of a load exceeding the resistance is at some acceptable (low) level. Figure 4 is easiest to understand in the framework of a maximum load resulting from an extreme event compared against a static strength measure. The strength (capacity) of a manufactured part is never known exactly nor is the extreme structural load a wind turbine component will experience. Therefore, characteristic values are selected from the upper range of possible loads and from the lower end of the strength distribution to establish a conservative starting point. Then, a safety factor is applied to each characteristic quantity, commensurate with the total uncertainty and calibrated for a target reliability. The safety factors on the characteristic loads, γL, are sometimes borrowed from older fields (such as wind engineering for buildings or bridges), and an assumption is made that the know-how needed to convert wind speed to loads is similar. Strength (also called resistance) safety factors, γR, are derived by applying a cascade of “knock-down factors” to the inherent strength of the material based on the quality of the manufacturing process and underlying material property variability at relevant spatial scales, which are discussed in Sect. 8. Both these factored terms (on load and resistance) lead to the design criterion

which, as is evident, requires an inflated load to be less than a knocked-down strength. All the quantities in such design equations should continue to evolve. Advances in the ability to simulate complex loads and represent resistance variables lead to refinement in characteristic values, whereas improved understanding of all uncertainties in loads and resistance leads to fine-tuning the safety factors. Such progress and refinements are especially needed in new locations such as offshore, where calibration studies informed by simulation and testing are key.

The idea of a characteristic load is easiest to understand in the context of an extreme or highest wind speed, but there are many other situations in which an operating wind turbine must be evaluated relative to its loading. For example, the characteristic “load” for fatigue is sometimes defined after first deriving a distribution of cyclic load amplitudes driven by some specified inflow over the turbine's design life. A distribution that represents the more severe end of all possibilities is created by assuming an enhanced (extreme) turbulence level; such a conservative distribution effectively envelops the real distribution. The developers of early editions of the International Electrotechnical Commission (IEC) 61400-1 design standard back in the 1990s defined a set of design load cases (DLCs) that now includes 23 specific situations or characteristic loads against which the structure must be shown to survive and remain operational. These DLCs include consideration for turbines parked in extreme winds, operating in normal or extreme turbulence at all wind speeds, wind gusts and direction changes during operation, shutdowns during gusts, operating or shutting down with a control fault, and various combinations of these situations. Each of these DLCs produces a characteristic load that poses a threat to either the ultimate strength or fatigue durability of the primary structure and hence to the survival of the system. It is assumed that selected aeroelastic models can convert these design situations into loads everywhere in the structure and that these 23 situations collectively represent the key risks to survival.

3.2 Inflow modeling

Establishing an appropriate characteristic load for a wind turbine component is a challenge because of the extreme variability in external conditions. During the design phase, the atmospheric conditions must be modeled in a way that drives an aeroelastic calculation of characteristic loads that are robust with respect to a variety of potential site conditions, but this is not an easy task. A wind turbine installed in the mountains experiences a substantially different load profile than one floating offshore. To complicate matters, the loading distribution for each wind turbine has a large spread because of the stochastic nature of turbulence, which adds uncertainty to the characteristic load calculations. The largest turbines in the market today regularly extend to above the top of the atmospheric surface layer; therefore, the turbulence at the top of the rotor may be significantly different than at the bottom, and wind shear may deviate from standard assumptions as well. Although the wind industry has enhanced the state of the art such that multi-megawatt turbines can be successfully designed and deployed, gaps remain that hinder the innovation necessary for continuous improvement.

One of the greatest challenges in design inflow definition results from limitations in the turbulence models used in the design standard. For example, the two turbulence models specified in IEC 61400-1 use parameters that were fit to limited data from relatively short meteorological masts (Kaimal, 1990). Moreover, inflow conditions generated using the two models exhibit substantial differences (Nybø et al., 2020). These differences in inflow definitions lead to different loads (Eliassen and Andersen, 2016; Doubrawa et al., 2019); sometimes these results are even contradictory, and such differences remain to be thoroughly investigated. Other work notes that what designers use as an “extreme turbulence model” (IEC, 2019) might not reflect any real conditions (Hannesdóttir et al., 2019; Moon and Sahasakkul, 2014), and the extreme events, in particular wind gust definitions, may be non-conservative at some sites (Rakib et al., 2020). Extreme events, such as thunderstorm downbursts, can have spatial and temporal characteristics that are quite distinct from IEC design load cases, as noted in analytical models that match recorded events (Nguyen et al., 2011), as well as in large-eddy simulation (LES) Weather Research and Forecasting models of realistic downbursts (Hawbecker et al., 2017). Lastly, the shear model assumes a wind turbine operating entirely within the atmospheric surface layer, which is not appropriate for the size of modern-day turbines. Other inaccuracies in the assumed turbulence models exist but cannot be listed because of brevity.

Besides the noted inaccuracies, there are several other phenomena that are missing in current inflow models that likely have a significant impact on design loads. For example, design inflow conditions do not include veer, and yet published results indicate that loads are quite sensitive to it (Robertson et al., 2019). Only simple power-law vertical mean profiles without veer – which are representative of only a neutral boundary layer – are suggested in design standards. Stable boundary layer conditions that occur for longer times over each diurnal cycle can introduce veer, enhanced shear relative to the power-law profile, and even low-level jets (Park et al., 2014; Rife et al., 2010; Banta et al., 2002). In general, during times of day associated with significant electricity demand, such as during and slightly after the evening transition period, ABL conditions undergo contrasting convective, near-neutral, and stable stratification with associated differences in wind velocity fields not considered in DLCs (Lu et al., 2019) yet important when turbine loads are considered. Non-Gaussian characteristics in wind velocity field structure functions are also not typically considered in inflow design definitions, although it has been shown that extrapolated design loads can be significantly affected by their inclusion (Gontier et al., 2007; Berg et al., 2016; Moeng and Rotunno, 1990). The Kaimal spectral model in IEC 61400-1 does not offer any guidance on spatial coherence in lateral and vertical turbulence components, which reduces those components to noise. In general, coherence functions as defined in IEC 61400-1 are not consistent with measurements over wind turbine rotor spatial separations, as found from limited field studies (Saranyasoontorn et al., 2004). Vortex-induced vibrations that arise in parked turbine cases resulting from extreme wind flow angles cannot be captured without high-fidelity simulations, such as vortex codes or computational fluid dynamics (CFD) codes (Zou et al., 2014). Despite all the noted inaccuracies and inexact or missing phenomena in the inflow models currently in use, the industry experience has not uncovered frequent failures of the primary structure, which indicates that assumptions of overly energetic inflow turbulence, accompanied by sizable safety factors, are producing conservative designs. However, the size of modern-day wind turbines is such that inaccuracies in existing inflow models may prove to be unsustainable for cutting-edge design and to trim margins in overdesign (Hannesdóttir et al., 2019). This combination of overly energetic inflow with large safety factors is a rather blunt instrument for design and effectively limits the options that can be considered within reasonable boundaries of risk. Therefore, reducing the uncertainties and inaccuracies in the inflow conditions as much as possible would help enable the innovation essential for progress.

In recent work, there have been developments outside of the IEC inflow models that might eventually prove to be essential in future revisions and improvements of standards for load definitions. Of particular interest is the continual development of high-fidelity flow-field simulators, most notably using LES, as shown in Fig. 1. Although there have been some comparisons reported between loads generated with LES and those based on stochastic simulation using the two spectral models in IEC 61400-1 (Doubrawa et al., 2019; Park et al., 2015), there is little published work establishing which of these methods can best reproduce measurements. LES offers the unique ability to simulate mesoscale events and structures, which could prove extremely beneficial in simulating a turbine's response in a plant, even for complex and extreme transient events such as thunderstorm downbursts (Hawbecker et al., 2017; Lu et al., 2019). However, the best method to couple such mesoscale simulations with microscale physics is currently unidentified, and the potential effect on loads is also unknown.

Additional work is needed to design turbines that operate in non-standard conditions. Design conditions within the IEC standard have historically assumed uninterrupted flow and, until recently, relatively simple terrain. However, more and more turbines are being installed in locations where their inflow conditions do not match that assumption, whether it be offshore, in complex terrain, or in waked conditions within a plant. Offshore conditions, even considering only wind fields, are associated with greater uncertainty than for land-based applications, even though it is generally assumed that offshore winds are accompanied by lower turbulence intensity and higher mean wind speeds. Today, there is no classification system (i.e., design class definitions) for different meteorological oceanographic (metocean) conditions, thereby implying that offshore turbines must either be certified using land-based classification, which likely results in a sub-optimal design, or custom designed and certified for each site's local climatology. Finally, many turbine units in wind plants (especially with deep arrays) will never experience inflow conditions as prescribed in the standard, as a result of the presence of wakes generated from adjacent upstream turbines. Although much work has been done on the modeling of wakes and the resulting effects on wind turbine power production and loads, a final standard-based connection to the inflow conditions useful at the design stage has yet to be established.

The wind energy field would benefit from robust techniques to create full-field turbulence data from atmospheric measurements. In aeroelastic evaluation of a wind turbine design, it is essential that turbulence fields used in the simulation studies are as realistic as possible to ensure an accurate prediction of loads. As noted previously, there are considerable deficiencies in existing turbulence methods; they are often unrealistic and run counter to observations. One possible method to increase the accuracy in turbulent fields is to incorporate wind measurements into the stochastic turbulence generation process, thereby capturing real phenomena and improving the accuracy of the predicted results. There are several methods that have been proposed (Rinker, 2018; Dimitrov and Natarajan, 2016), but their robustness and accuracy have not been demonstrated. Moreover, the techniques generally assume either a Mann or Kaimal spectral model, which could be inaccurate depending on the flow conditions (as noted earlier). If a technique to reconstruct turbulence fields from measurements could be adequately developed, demonstrated, and regulated, it not only could benefit the wind turbine design process but also could be used to reduce loads during operation.

In summary, and considering the previous discussion points, it is clear that there are still several challenges regarding modeling of inflow during the turbine design process. An especially significant opportunity for improvement is related to the two spectral models allowed in the IEC design standard, both of which may be non-conservative depending on the loading conditions (Doubrawa et al., 2019). Several other important phenomena (e.g., non-Gaussian wind velocity field structure functions, wind veer, non-stationary turbulence) are not addressed in current wind turbine design practices, and their omission should be either justified or corrected. The most open fields for research are in high-fidelity modeling, such as in the use of LES mesoscale modeling during the design process, and in reconstructing full-field turbulence from measurements. Reducing knowledge gaps in these areas is expected to lead to more accurate design loads, which will improve wind turbine designs and advance the wind energy field as a whole.

3.3 From inflow to design loads

The process of propagating inflow to simulated turbine loads is by no means straightforward. In the current design process, it is customary to employ a blade element momentum (BEM) model with inflow conditions as specified in the design standard. However, this method and its simplifying assumptions limit the model's versatility and accuracy in many realistic situations. Longer and more flexible blades, for instance, not only result in large structural deflections but also invalidate key linearity assumptions made in simpler aerodynamic models for wind turbines, as discussed in Sect. 5. Wind turbine controllers are becoming increasingly adaptable on the fly, in response to varying inflow conditions (Sect. 4); however, at the same time, differences between the expected and true inflow can lead to large load discrepancies.

The placement of turbines in wind plant arrays complicates load calculations further. Expanding the control strategy to go from considering a single turbine to an entire wind plant necessitates full plant-level simulations. Plant-level control strategies can be implemented to optimize production, respond to grid demands, and so on (see Sect. 4), but the aero-servo-elastic response of each turbine in the plant is still unique and needs to be considered separately. Furthermore, the wakes within a plant propagate to each turbine differently, and their propagation depends on additional atmospheric parameters that are not typically considered in design load calculations (e.g., wind direction or atmospheric stability; see Sect. 7). The calculation of loads for modern-day turbines, regardless of whether they are standing alone or within a plant, is therefore an area in which useful advances can be made.

Wind turbines are designed so that loads remain within material strength limits in both fatigue and ultimate limit states. These two design constraints are quite different in nature. Fatigue loads account for a cumulative effect that requires consideration of the entire loading spectrum resulting from exhaustive consideration of operational conditions over the design life of the turbine. While fatigue damage is less sensitive to any single loading event, it requires all loading sources to be aggregated and applied to the selected damage accumulation model for each individual component. The combination of both fatigue and ultimate strength design evaluation requires that aeroelastic models be able to represent extreme events that appear at the corners of the design space, as well as simulate a sufficiently large ensemble of typical operating cases, to estimate lifetime distributions of fatigue loads. Existing damage models are typically simple, using linear damage accumulation laws such as Miner's rule to calculate fatigue life (material strength and damage modeling are addressed in greater detail in Sect. 8). Ultimate loads result either from extreme wind conditions at the site while the turbine is parked or from the largest loads that arise during normal operation over the service lifetime. The extreme values in each case also depend on how the control system interacts with the inflow at the site and include events so rare that they are impossible to establish empirically during a typical site assessment. Extremes are also difficult to estimate computationally because current simulation capabilities are not validated for unusual atmospheric conditions. The various types of extremes, no matter how they are generated, are stochastic in nature and must also include atmospheric extremes of stability, low-level jets, discrete storms, and other such details now omitted from design specifications.

3.4 How models and data dealing with capacity influence reliability-based design

The preceding sections serve to illustrate how external conditions, inflow models, and a probabilistic design philosophy accommodate variability on the “demand” side in a probabilistic design paradigm. The other side of this design framework deals with the “capacity” of wind turbine systems that must rationally, economically, and safely be balanced against imposed demands. Often, the intrinsic (aleatory) variability in coupons, components, assemblages, and subsystems must be accounted for, and, equally important, there is a need to deal with imperfect models, limited test data, etc. that translate to epistemic uncertainty. Reliability-based design needs to capture all of the load- or demand-side variabilities with their own complexities along with capacity-side uncertainties. The following discussion deals with these capacity-specific challenges in design.

After loads are calculated, the resistance of the structure to those loads must be evaluated. This evaluation includes the ability to withstand both ultimate and fatigue loads, remain in structural and dynamic stability regimes, and accommodate anticipated deflections. For ultimate loads, material coupon tests are performed to evaluate limit states, typically on a basis, which means ensuring that there is a 95 % probability of meeting a specified limit state with 95 % confidence. Composite materials require more extensive testing than metals, as associated limit states depend on both material orientation and loading direction. Fatigue resistance requires either the cyclic testing of materials at a given load amplitude and mean level until failure or testing at this loading level for a specified number of cycles and then assessing the remaining strength. Material properties assessed in this manner are then used as a starting point for resistance calculations, wherein they are further reduced (conservatively) by applying a series of multiplicative safety factors that account for uncertainties in the effects of environmental conditions, temperature effects, the presence of manufacturing flaws, the accuracy of the analysis method, and the fidelity of the load characterization. After inclusion of all these safety factors, “design” values are thus established, which in many cases results in a value of only one-half to two-thirds of the initial resistance obtained from material testing. Structural and dynamic stability must also be evaluated for wind turbine components. Structural stability issues, one manifestation of which involves buckling, typically affect blades and towers and can occur at much lower loads than would cause ultimate failure of the materials. Dynamic stability issues, including both system resonance and aeroelastic instabilities, require an evaluation of the interaction of atmospheric forcing and the dynamics of the structural component (e.g., blade), ensuring that vibrations are adequately damped during operation and do not lead to catastrophic failure of the machine. Finally, for blades, a critical deflection analysis, focused mainly on stiffness considerations, is performed to ensure that they do not strike the tower under extreme loading conditions.

3.5 Probabilistic considerations for capacity

Wind turbine structures and components have historically been designed using deterministic approaches based on industry-standardized methods of defining structural loads, material resistances, and factors to establish margins of safety. Such approaches have resulted in hardware that has a high reliability with respect to primary structural survival, whereas individual components have often proved to be insufficiently reliable compared to industry expectations. The goal of existing standards is to ensure that no more than 1 % of hardware will fail during a defined 20-year life. On average, major component failure rates are higher than this, particularly with respect to main bearings, gearboxes, and rotor blades (Dao et al., 2019). In some cases, these failure rates reflect uncertainty in defining the structural loads and material characteristics that fall outside assumptions inherent in the deterministic methods and the accompanying prescribed safety factors that are intended to accommodate that uncertainty. In other cases, the root causes of the failure mode are not well-understood or easily characterized.

As a result, efforts are underway to advance wind turbine and component design to integrate reliability-based approaches that could result in reducing the LCOE to levels previously considered unrealizable. Such approaches can better account for the uncertainties in the structural loads resulting from the relevant inflow conditions and operational response, as well as for the variability in material characteristics arising from differences in materials and manufacturing processes. Historically, the wind energy industry did not have sufficiently long operational history records that could serve to empirically validate such probabilistic models. However, the industry has now acquired nearly 40 years of field experience and 20 years of experience with multi-megawatt turbines that have converged to a relatively consistent architecture (three blades, pitch control, variable speed, etc.). This experience, combined with new material and structural test methods, should allow for a better accounting of the effects of uncertainty in design. Admittedly, operational data – while useful and inherently related to failure rates with a time-in-use basis to assess reliability – may not be directly compared against other reliability-based targets and safety factors that are common in reliability-based design codes. Nevertheless, operational data and failure rates in the field can serve to assess effectiveness of design philosophies that are risk-based and that consider both demand and capacity uncertainties. Rational use of failure-rate data in reliability-centered maintenance programs is common, for example, in the aerospace and automobile industry; such practices are not yet codified for use in the wind energy industry, but experiences in the field with turbines can possibly also be adopted and perhaps even be part of life-extension strategies.

Adoption of reliability-based approaches to engineering, manufacturing, operation, and maintenance could result in a more realistic approach to managing the life cycle cost of ownership of wind energy assets. Key to the success of this approach will be implementing cost-effective methods of manufacturing process quality assurance and quality control that can better ensure that parts leave the factory with acceptably small nonconformities using, for instance, statistical quality control. This process is presently particularly challenging with respect to rotor blades, primarily due to their size. Although many original equipment manufacturers perform ultrasonic inspections or use similar non-destructive testing on some of the critical load-carrying components (e.g., spar caps), in general much of the blade structure is fabricated without strict quality control that can guarantee conformities with all critical-to-quality elements of the design stipulated by engineering. Given the low-cost requirements of the industry, quality assurance associated with many such manufacturing processes does not necessarily guarantee conformity with statistically quantifiable reliability. Evolving to reliability-based approaches will require the adoption of such quality assurance and quality control methods that can ensure quantifiable quality.

Rather than establishing unrealistic expectations for decades of low-maintenance operation, new methods must rely upon cost-effective intervals for inspection and proactive maintenance, establish up-front expectations for major component replacements, and ultimately produce estimates of remaining useful life as plants age. Many other mature industries, including aviation and nuclear power generation, rely on reliability-based approaches and reliability-centered operations and maintenance programs, so the techniques are well-established; however, similar programs will need to be adapted to the unique characteristics of the wind energy industry. The challenge ahead is to integrate the probabilistic analyses that quantify loads and demands with manufacturing, quality control, and operational experience and field performance data in a rational, risk-based design framework.

3.6 A new design philosophy