the Creative Commons Attribution 4.0 License.

the Creative Commons Attribution 4.0 License.

Current status and grand challenges for small wind turbine technology

Alessandro Bianchini

Galih Bangga

Ian Baring-Gould

Alessandro Croce

José Ignacio Cruz

Rick Damiani

Gareth Erfort

Carlos Simao Ferreira

David Infield

Christian Navid Nayeri

George Pechlivanoglou

Mark Runacres

Gerard Schepers

Brent Summerville

David Wood

Alice Orrell

While modern wind turbines have become by far the largest rotating machines on Earth with further upscaling planned for the future, a renewed interest in small wind turbines (SWTs) is fostering energy transition and smart grid development. Small machines have traditionally not received the same level of aerodynamic refinement as their larger counterparts, resulting in lower efficiency, lower capacity factors, and therefore a higher cost of energy. In an effort to reduce this gap, research programs are developing worldwide. With this background, the scope of the present study is 2-fold. In the first part of this paper, an overview of the current status of the technology is presented in terms of technical maturity, diffusion, and cost. The second part of the study proposes five grand challenges that are thought to be key to fostering the development of small wind turbine technology in the near future, i.e. (1) improving energy conversion of modern SWTs through better design and control, especially in the case of turbulent wind; (2) better predicting long-term turbine performance with limited resource measurements and proving reliability; (3) improving the economic viability of small wind energy; (4) facilitating the contribution of SWTs to the energy demand and electrical system integration; (5) fostering engagement, social acceptance, and deployment for global distributed wind markets. To tackle these challenges, a series of unknowns and gaps are first identified and discussed. Based on them, improvement areas are suggested, for which 10 key enabling actions are finally proposed.

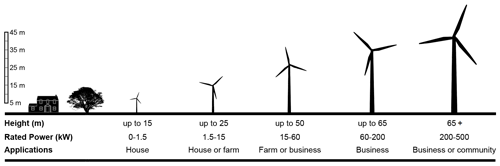

A major portion of today's installed wind power is in the form of large wind power plants, which mainly consist of multi-megawatt machines (GWEC, 2020), while a clear trend in further upscaling of both rated power and dimension is ongoing (Veers et al., 2019). Small wind turbines (SWTs) are, however, still visible around the world for a variety of applications, including electric power generation for households, industrial centers, farms, and isolated communities; combining with other energy sources and storage in hybrid energy systems for electricity to support remote monitoring and telecommunications; and providing direct energy services for applications such as water pumping, desalination, and purification (Chagas et al., 2020). The use of wind turbines in rural areas is of particular relevance for some countries; for example, around the Horn of Africa, small wind systems are the most viable solution in the scarcely electrified parts of those countries (Gabra et al., 2019). Karekezi (2002) reported that South Africa has more than 100 000 wind pumps in operation used at over 45 818 farms. SWTs are a subset of a larger distributed wind market segment that can include large turbines installed in distributed applications. Figure 1 associates typical distributed turbine sizes with their main types of application.

Figure 1Small and distributed wind turbine dimensions and rated power outputs as a function of various applications.

When SWTs are used for a variety of ancillary purposes other than electricity production such as ventilation or water pumping, different turbine concepts can come into play. These applications may use the Savonius vertical-axis turbine (Akwa et al., 2012) or the multi-blade American windmill (Baker, 1985), which constitute a small space on the market. Although these machines are in all respects SWTs, they are not discussed in the present study, which instead focuses on SWTs for electricity production.

Before moving forward, a key element of this study is defining what is meant by “small wind turbine”. A universal consensus on this has not been reached, with the International Electrotechnical Commission (IEC) Standards (IEC – International Standard, 2019b) defining SWTs as turbines with a maximum rotor swept area of 200 m2; the same threshold is applied to eligible turbines for certification by the AWEA Small Wind Turbine Performance and Safety Standard 9.1-2009; however, a new American National Standards Institute consensus standard, ACP 101-1, is being developed by the American Clean Power Association (ACP), the successor to the AWEA. ACP 101-1 is intended to eventually supersede the AWEA 9.1-2009 standard (Summerville et al., 2021). Several countries use rated power as the key differentiator, and ACP 101-1 thus defines SWTs as having a peak power of 150 kW or less and microturbines as having a peak power up to 1 kW. In Brazil, small wind systems are categorized as power stations (which could be composed of one or many wind turbines) with a total rated capacity below 100 kW, according to Resolution 438/2012 of the Brazilian Electricity Regulatory Agency (ANEEL) (Chagas et al., 2020).

The importance of having a more comprehensive definition of “small wind” has been recently put in the spotlight. For example, it has been suggested by the Small Wind Turbine Technical Committee of the European Academy of Wind Energy (EAWE) that many problems and technical challenges of SWTs are common to the majority of the rotors up to 500 kW (EAWE, 2020), i.e., also extending to distributed wind turbines (DWTs). As is further discussed in the present study, it is important to more clearly define those characteristics that make SWTs unique from utility-scale turbines. However, this is not an easy task because significant variability in wind turbine design is also apparent, with no specific size-based design threshold. Additionally, there are a variety of “alternative” configurations available on the open market (Bianchini, 2019), such as vertical-axis turbines (Aslam Bhutta et al., 2012), diffuser-augmented wind turbines (Evans et al., 2020), or first prototypes of airborne wind energy (AWE) converters (Meghana et al., 2022). Even though SWTs may still represent a niche application within the wind energy market, they have recently been exhibiting a notable rate of growth concomitant with the diffusion of smart energy systems (Tzen, 2020). This diffusion, however, is still hindered by the typically higher costs of small wind systems. These increased costs are driven by several factors, including a lack of development and system optimization and issues related to those cost items (i.e., electrical connection, resource assessment expenses, installation cost, etc.) that are not proportionally lower for smaller projects (Simic et al., 2013). The growth of the SWT sector is further notable in light of the several published reports showing that SWT installations have failed to reach their expected energy yield, resulting in underperforming turbines. This is particularly true in the case of installations in the urban or built environment (WINEUR project, 2005; Fields et al., 2016). Development in highly complex areas, such as urban locations, is complicated due to the wind conditions in the city's canopy layer, which typically have low intensity, high variability, high levels of turbulence, and inclined or even reversed airflows. While several studies have shown a theoretically good potential for urban wind (Balduzzi et al., 2012; Toja-Silva et al., 2013), a number of challenges still need to be tackled to effectively fit wind energy converters to this environment, as recently discussed by Micallef and Bussel (2018) and Stathopoulos et al. (2018). In the present study, the authors decided not to include a specific technical analysis of the needs for urban wind, although future work on the topic has to be encouraged (Battisti, 2018).

Even so, projections of SWT deployment in future scenarios of distributed energy production within smart grids (thus in proximity to populated areas) are considered promising. In this sense, SWTs are expected to provide a significant contribution, especially in combination with other renewable energy sources. However, the higher levelized cost of energy (LCOE) of SWTs, especially compared to residential solar photovoltaics (PVs), still hampers the massive diffusion of this technology.

1.1 A guide to this article

The present study has two main focuses. First, it provides an overview of the status of SWT technology. We present the market diffusion and economics of SWTs (Sects. 2–3) with the goal of placing the technology in the current energy market and defining some important threshold values. We then provide a description of the main technical features of SWTs (Sect. 4) and compare them to those of their utility-scale counterparts. Section 5 pursues the second focus of the work, defining five grand challenges that – per the authors' assessment – are key to fostering the development of SWTs in the near future. More specifically, a series of unknowns and gaps for SWTs is first defined, and then the main improvement areas and prospects are proposed to address those gaps. Finally, Sect. 6 synthesizes the main outcomes of the study into concluding remarks and defines 10 key enabling actions for achieving the grand challenges in the near future.

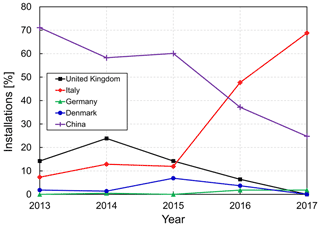

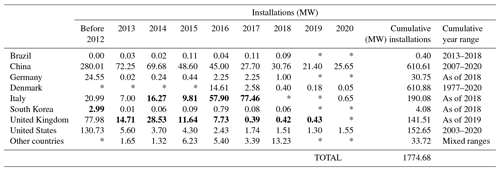

There is at least ∼ 1.8 GW of installed small wind capacity globally from over 1 million turbines (Orrell et al., 2021). The global spread of this electrical capacity, including all types of turbines and based on available reports from some key surveyed countries, is shown in Table 1 (asterisks denote a lack of validated data for that specific year). Figure 2 provides a more focused insight into several of those countries, which showed notably different trends in the first years of the last decade, where SWT technology saw one of its more interesting phases. While Denmark, the United Kingdom, and the United States have a long-recorded history of small wind installations, China has added larger amounts of small wind capacity more consistently in recent years. On the other hand, Italy and the United Kingdom, which saw many installations in the first decade of the century, both experienced recent decreases due to feed-in tariff (FIT) policy changes. FITs provide payments to owners of small-scale renewable generators at a fixed rate per unit of electricity produced, verifying that the cost of the installation is recovered over the lifetime of the generator. In the case of Italy, in particular, the significant increase in installations seen around 2016–2017 was due to a special program of incentives for turbines under 60 kW. The FIT rate in Italy declined over time before expiring in 2017. It was replaced by the FER1 Decree in 2019 (Dentons, 2020). In line with these changes, an estimated 77.46 MW of wind projects using turbines sized up through 250 kW was installed in Italy in 2017, no installation reports were available for 2018 and 2019, and 0.65 MW of projects was reported for 2020. The United Kingdom closed its FIT program to new applicants in 2019 and introduced the Smart Export Guarantee program. Under that program, applicants now receive a tariff determined by the buyer rather than a fixed price determined by the government (Ofgem, 2021). Consequently, small wind deployment went from 28.53 MW in 2014 to only 0.43 MW in 2019 (Orrell et al., 2021). In a scenario of decaying government incentives, an outlier case in Europe is Greece (Greek Government Gazette, 2021), which still offers an FIT for SWTs. At the time of writing this paper, the program was for 20 MW installed capacity, starting with a tariff of EUR 157 per megawatt-hour (USD 181 per megawatt-hour) that will be automatically reduced based on the cumulative contracted power of the projects. A bonus with respect to the tax break is also in place, which brings the FIT to EUR 163 per megawatt-hour (USD 187 per megawatt-hour).

Table 1Small wind turbine installations through 2020. Data from Orrell et al. (2021) and Chagas et al. (2020). Values in bold refer to years/countries with FIT schemes in place. Asterisks refer to missing data for that specific year.

Other examples of these tariffs include those in Japan and the Republic of Korea. Japan's FIT program was established in the wake of the Fukushima Daiichi nuclear disaster. Its rates have steadily declined, from a peak of JPY 55 per kilowatt-hour in 2015 to JPY 19 (approximately1 EUR 0.125 or USD 0.175) per kilowatt-hour as of 2019 for turbines less than 20 kW (Orrell et al., 2021). The Republic of Korea also had an FIT program, but it was ended in 2012 and replaced with a renewable portfolio standard (Lo, 2018). While the switch from the FIT program increased capacities in some renewables in the Republic of Korea, such as biomass co-firing and fuel cell deployment, small wind installations dropped (Orrell et al., 2021).

The discontinuous nature of incentives and national programs makes it difficult for manufacturers to stay in the market, even in those countries where SWT technology is more present, as in the UK, Italy, and the United States. Six small wind manufacturers in the United States reported international exports in 2015, with just three doing so in 2020 (Orrell et al., 2021). Similarly, sales in China and exports from China have fluctuated with the number of Chinese small wind manufacturers in that market. In 2017, only 15 Chinese small wind turbine manufacturers reported sales, a decrease from 28 in 2014 (Duo, 2017), corresponding to a 60 % drop in sales from 2014 to 2017 (Orrell et al., 2021).

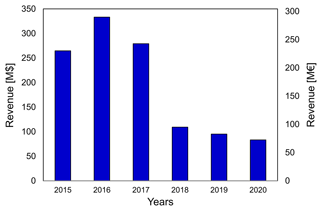

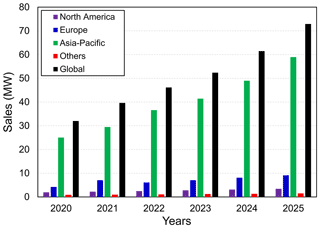

From a global perspective, at the time of writing this paper, the largest market for small wind still came from Europe, the United States, and China. SWTs are most commonly used for off-grid applications, such as telecommunication towers and farming. They are also used to power individual homes and small businesses, which can be tied to the grid. In 2019, 94 % of SWT sales went to off-grid applications (Global Info Research, 2021). Unfortunately, 2020 saw only about 30 MW worth of units being sold around the world (Orrell et al., 2021), with a global market in terms of revenues (Fig. 3) still on a flat trend. Regarding future perspectives (Global Info Research, 2021), no clear agreement on future perspectives was found at the time of writing, mainly as a consequence of the financial crisis connected to the global COVID-19 pandemic in 2020. Global Info Research (Global Info Research, 2021) predicted the SWT global market would reach USD 190 million (EUR 165 million) in 2025, with a compound annual growth rate of 11.45 % from 2020 to 2025. The market could thus become promising again, especially in connection with the increasing attention on the transition toward cleaner energy systems. Regarding the future share by region, Europe, Asia-Pacific, and the United States are expected to remain the key players in this sector. In particular, the Asia-Pacific market will lead the total worldwide SWT sales, while the European market will show a reduction in the global relative share (Fig. 4). In Asia, Japan is expected to deploy renewable energy generation at large scales following the Fukushima Daiichi nuclear disaster, whereas other countries such as Malaysia – which represents an untapped market with suitable conditions for SWTs (Wen et al., 2019) – might also see significant deployment.

As described in Sect. 2, the diffusion of SWTs has often gone hand in hand with dedicated financial incentive programs from individual countries. This is unfortunately because the high LCOE of SWTs has represented the main obstacle hampering wider deployment of SWT technology (Predescu, 2016).

The economic evaluation of small wind systems is particularly critical for three main reasons: (1) the capital investment is strongly dependent on the specific turbine and country; (2) the correct selection of the installation site has a much higher impact on actual annual energy production (AEP) than in the case of turbines with large rotors; and (3) as discussed, the real viability of a project may depend completely on the incentives ensured by the specific country.

To give the reader an overview of the aforementioned issues, the main cost factors are analyzed in the following subsections to facilitate the comparison of costs by country or region for the same technologies and to enable the identification of the key drivers in any cost differences. The four key indicators are total installation cost, operation and maintenance cost, capacity factors, and LCOE.

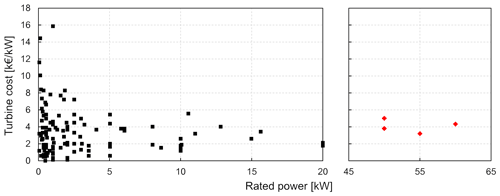

Figure 5Turbine purchase cost survey for rated power lower than 20 kW (Kaldellis and Zafirakis, 2012) and around 50 kW (authors' experience).

3.1 Total installation cost

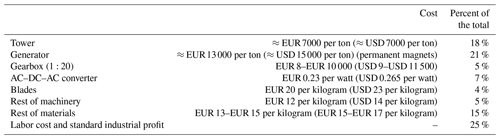

The total investment for installation can be expressed as the sum of the purchase cost and installation cost. The purchase cost for a SWT is notably variable not only as a function of the turbine size but also over time, depending on the attention given to the technology. Kaldellis and Zafirakis (2012) present a survey on 142 SWT models up to 20 kW, showing – as expected – a turbine cost reduction as a function of the rated power (black square markers in Fig. 5). Recent data from the authors' direct experience are also added as red diamonds in Fig. 5 for the SWTs with rated power outputs around 50 kW. As seen in the figure, the decreasing cost trend for lower rated power values is somehow stopped for rated power outputs around 50 kW. This can be explained considering that, from this size up, turbines become more complex, requiring specific features (e.g., the yawing system) and a manufacturing quality higher than that of smaller turbines. Finally, Bortolini et al. (2014) provide a more up-to-date market survey considering several producers located worldwide and confirm that purchasing costs are not so highly correlated to the plant sizes because of aspects related to the specific producer, e.g., producer country, producer cost structure, and market policies. Having direct information on how the global, or total installed, cost comes together is very rare. In this study, thanks to support from the Eunice Energy Group, a cost breakdown is presented in Table 2 for the 60 kW machine EW16 Thesis (Eunice Energy Group, 2021).

Table 2Capital cost breakdown of a 60 kW turbine (courtesy of the Eunice Energy Group). Weights reported in metric tons.

Wood (2011) reported a similar breakdown for a smaller machine (10 kW), showing how – in that case – the relative cost for blades becomes more relevant (7 %), while that of the generator becomes less significant (6 %) due to the lower power output.

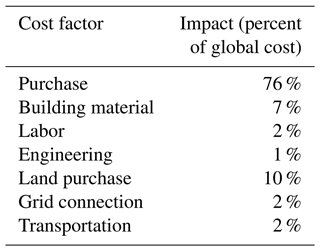

The installation cost is probably the most critical parameter to evaluate and includes seven primary factors.

-

Raw material cost, i.e., expenditures to purchase the materials required for the turbine installation as well as to lay the foundation. All these elements are correlated to the wind turbine's weight and height and to the rotor diameter.

-

Earthworks' cost, i.e., foundations, grounding, etc., to enable SWTs' operation. This is more crucial for countries with higher seismic activity that require more expensive foundations and is dependent on the type of soil.

-

Installation labor cost, i.e., workers' salary, crane rental, standby times on windy days.

-

Engineering cost, i.e., expenditures for the preliminary and executive drawings, feasibility study and engineering, and site assessment and wind resource assessment activities to estimate expected AEP as well as documentation of all deliverables.

-

Land purchase cost, i.e., cost for the required ground surface. Considering the tower height, a surface area of the same swept radius is assumed to be necessary. Additional cost for access roads, where not present, may be necessary.

-

Grid connection cost, i.e., cables, power unit, and control system, including license fees.

-

Transportation costs, i.e., the expenditures necessary to get the turbine to the installation site. Transportation costs can include two different types of trips. In the case of imported turbines, transportation by both sea (e.g., to reach the EU mainland) and land (i.e., to reach the final site) is needed.

The relative impact of these factors has been quantified by Bortolini et al. (2014) and reported in Table 3.

The engineering cost in Table 3 includes the wind resource and site assessment activities conducted to estimate a SWT's expected AEP. The low percentage of total cost for this cost factor is in line with similar research that found that many small wind installers do only minimal wind resource and site assessments (Orrell and Poehlman, 2017). This is partly because of the challenges involved in achieving a low-cost and accurate wind resource assessment. First, there are not many tools available and appropriate for small wind assessments. Next, for those installers who do attempt assessments, the tools regularly do not provide accurate AEP estimates because they mischaracterize the wind resource and perform poorly in areas of complex terrain well (Sheridan et al., 2022). Based on the experience of some of the authors, the cost for a resource assessment for a SWT project may be in the order of EUR 15 000 (USD 172 000), although this price is strongly variable from case to case, especially as a function of the site topography. In addition, one should also remember that the complexity of the terrain also affects accessibility to the grid, roads, price of the land, foundations, and the excavation works needed, thus also impacting the other items of the table.

Referring again to the 60 kW EW16 Thetis machine by the Eunice Energy Group, even though real costs are strictly project-dependent, the foundation cost can be broken down into approximately EUR 3000 (USD 3450) for the excavation (23 %), EUR 8000 (USD 9200) for the concrete (61 %), and EUR 2000 (USD 2300) for civil works (16 %). The transportation cost is approximately EUR 5000 per day (USD 5750 per day) (up to two trucks and up to 600 km), while the crane costs for a 50 t, 40 m crane are about EUR 6000 (USD 7200).

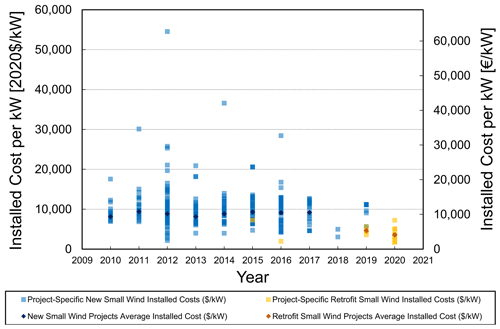

Figure 6Installed cost per kilowatt for newly installed or retrofit projects in the United States (Orrell et al., 2021).

An overview of the overall average annual and project-specific small wind installed cost (in 2020 USD) in the United States for 2010 through 2020 is presented in Fig. 6 (data from Orrell et al., 2021). Only new and retrofit projects with reported installed costs that use turbines with known rated capacities are included. Annual average capacity-weighted installed costs for new US small wind projects range from around EUR 3480 per kilowatt (USD 4000 per kilowatt) to nearly EUR 9565 per kilowatt (USD 11 000 per kilowatt). The small sample sizes and high variance in project-specific costs both contribute to this wide cost range. With the exception of 2018, the overall annual average capacity-weighted installed cost for this US dataset has remained relatively flat at approximately EUR 9260 per kilowatt (USD 9500 per kilowatt) (Orrell et al., 2021). This cost trend is in contrast with residential solar PV costs, which have been steadily dropping over several years (Barbose and Darghouth, 2015).

3.2 Operations and maintenance cost

Operations and maintenance (O&M) are conventionally clustered into a single cost term, but operation costs differ from maintenance costs, and not all distributed wind projects experience them equally. Operation costs for wind projects may include land lease payments, remote monitoring, various operations contracts, insurance, and property taxes. Operations are a significant expense for wind farms and large distributed wind projects; however, they typically are not substantial, or even present, for small, distributed wind projects. On the other hand, all wind projects, distributed or otherwise, require a significant maintenance cost (Orrell et al., 2021). For small wind systems, and especially in the case of complex areas, experience shows that usually an investor does not opt for installation sites with more than two SWTs in the same field or from the same owner. This consequently decreases the available room for the economy scaling on the O&M costs.

In most cases, the project installer or developer performs the maintenance for the system owner. Maintenance costs include labor, travel to the site, consumables, and any other related costs. Therefore, small wind maintenance costs can depend on the maintenance provider's proximity to the project site (i.e., travel costs), the availability of spare parts, and the complexity of maintenance and repairs. Maintenance costs can be categorized as scheduled or unscheduled. Scheduled maintenance activities can include inspecting the turbine, controller, and/or tower; adjusting blades; checking production meter and communications components; and providing an overall annual scheduled maintenance visit per the manufacturer's manual. Unscheduled maintenance activities can include a wide variety of activities, ranging from responding to a customer's complaint of noise from the turbine to replacing the generator, electrical components, inverter, blades, or anemometer. Scheduled maintenance site visit costs for a sample of small wind projects were collected for the Benchmarking US Small Wind Costs report (Orrell and Poehlman, 2017). Scheduled maintenance is typically performed annually. That data showed that the average scheduled maintenance cost per visit is about EUR 32 per kilowatt (USD 37 per kilowatt); the same value was confirmed by some European companies (Eunice Energy Group, personal communication, 2022). In general, upon combining different reference sources, it is reasonable to consider O&M cost for small wind projects in the range of 1 %–3 % of the initial investment (Tzen, 2020).

3.3 Capacity factors

The economic viability of SWTs depends in a complex way on several factors, including the life-cycle energy production and the possible presence of incentives. To address the first issue, i.e., to correctly evaluate actual production, a key metric is the capacity factor.

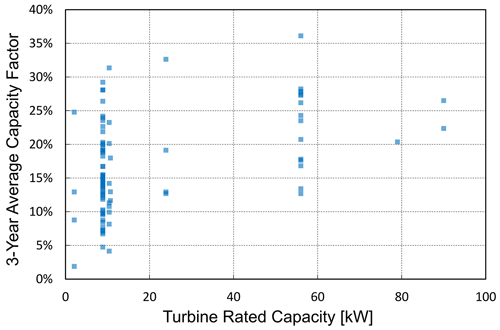

Figure 7The 3-year-average capacity factor for several US wind projects. Data from Orrell et al. (2020).

Boccard observed mean values below 21 % in 2009 (Boccard, 2009), while more recent works observed values between 37 % and 40 % (US DOE, 2015). Figure 7 presents calculated capacity factors for SWTs installed in the United States, based on the average of the first 3 years of reported generation for each project from the New York State Energy Research and Development Authority and US Department of Agriculture Rural Energy for America Program datasets and the turbine rated capacity (Orrell et al., 2020).

The 3-year-average capacity factor for small wind is 17 %, but the dataset includes a range from as small as 2 % to as high as 36 %. This large variability reflects, more than other variables, the challenges to SWT siting and site suitability. For example, the capacity factors for the 8.9 kW rated capacity turbines range from 5 % to 29 %. This means that the same turbine model sited in different locations can achieve very different capacity factors. Overall, the wind resource quality has the largest impact on capacity factors, even though technology improvements have raised turbine power outputs significantly. Therefore, the wide variation in capacity factors across markets is predominantly due to differing wind resource qualities and, to a lesser extent, the different site configurations and technologies used.

3.4 Levelized cost of energy

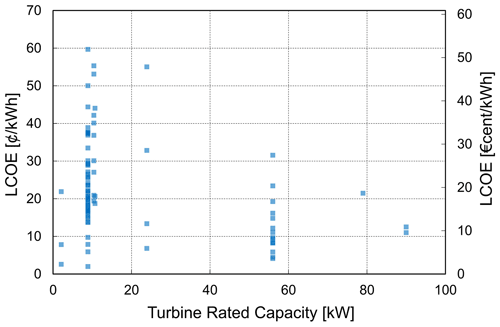

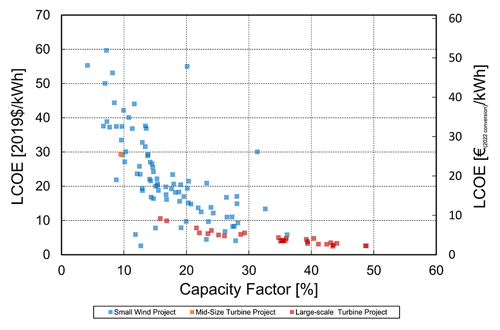

Scattered data regarding the LCOE of SWTs can be found in the literature and relevant reports. One of the most complete databases is provided by Orrell et al. (2020), who collected the data reported in Fig. 8 (prices are in cents of USD/EUR) for the US market.

The small wind average LCOE after incentives was EUR 0.2 per kilowatt-hour (USD 0.23 per kilowatt-hour) (from 86 US projects totaling 2 MW in rated capacity). To put these numbers in perspective, the LCOE of SWTs may be compared to the average residential retail electric rates ranging from approximately EUR 0.07 to EUR 0.17 per kilowatt-hour (USD 0.08 to 0.20 per kilowatt-hour) in the continental United States (Orrell et al., 2019) and to the LCOE of residential PVs, which is below EUR 0.087 per kilowatt-hour (USD 0.10 per kilowatt-hour). Recent experiences in Europe for turbines in the range of 50 to 60 kW showed potential for a significantly lower LCOE on the order of EUR 0.12 per kilowatt-hour (USD 0.0014 per kilowatt-hour) (Eunice Energy Group, personal communication, 2022). The relationship between calculated LCOEs after incentives and capacity factors is shown in Fig. 9. As expected, the higher the capacity factor, the lower the LCOE in general. Higher capacity factors, which in turn can reduce LCOEs, can be achieved by better siting, which can help increase energy production and better turbine operations (i.e., higher turbine availability).

Figure 9Relationship between LCOE and capacity factor for SWT projects. Data from Orrell et al. (2020).

Regarding the European Union, to the best of the authors' knowledge, there is no systematic study of the LCOE of SWTs, but there are a number of studies that point to higher LCOEs than those reported for the United States. For a site with a mean annual wind speed of 4.77 m s−1, Bukala et al. (2016) estimate a yearly energy production of 7551 kWh for a SWT with a rated power of 5 kW, neglecting downtime. They estimate the investment cost of such a wind turbine at EUR 36 500 (USD 42 000), which is lower than that in the data reported for the United States. For a discount factor of 4 % and assuming a yearly operation and maintenance cost of 2 % of the investment cost, an LCOE of EUR 0.45 per kilowatt-hour (USD 0.52 per kilowatt-hour) is produced without incentives.

For a SWT with a rated power of 3.5 kW installed at an agricultural site in Belgium with a mean wind speed of 4.13 m s−1, Tordeur (2018) reports an LCOE of EUR 0.36 per kilowatt-hour (USD 0.415 per kilowatt-hour) without incentives. This, coupled with all the incentives from which a small to medium agricultural enterprise may benefit in Belgium at the time of the measurement campaign (2016) and accounting for a discount rate of 4 %, gives a discounted payback time of 19 years. It is worth noting that the true cost of this project was a very low EUR 4300 per kilowatt (USD 4950 per kilowatt). The low cost is partly explained by the fact that the farmer acquired the tower separately at reduced cost and performed most of the installation himself. Even with such major cost-cutting, the SWT is not economically viable, indicating that a mean wind speed of 4.13 m s−1 is too low for a viable SWT project.

Bryne (2017) reports the metered energy output for a number of sites in Ireland. For a site with a mean wind speed of 6.1 m s−1, the AEP of a 5.2 kW rated wind turbine is 14 947 kWh, and for a site with a mean wind speed of 4.7 m s−1, the AEP of a 2.1 kW rated wind turbine is 3816 kWh. Assuming again a discount rate of 4 %, a yearly operation and maintenance cost of 2 % of the investment cost results in LCOEs of EUR 0.33 per kilowatt-hour (USD 0.38 per kilowatt-hour) and EUR 0.51 per kilowatt-hour (USD 0.59 per kilowatt-hour) for the 5.2 kW and 2.1 kW turbines, respectively, if the average installed cost per kilowatt from Orrell et al. (2019) is used. LCOEs of EUR 0.14 per kilowatt-hour (USD 0.16 per kilowatt-hour) and EUR 0.22 per kilowatt-hour (USD 0.25 per kilowatt-hour) are produced, respectively, if the average installed cost per kilowatt from Tordeur (2018) is used.

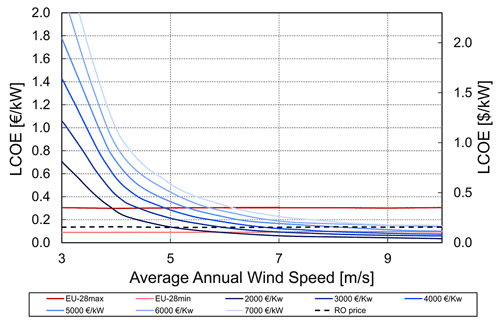

Figure 10LCOE trends versus annual average wind speed at different specific investment values in EU. Data from Predescu (2016).

Figure 10 presents the results of a study of the LCOE trend versus annual average wind speed at different specific investment values, with the household energy purchasing prices in EU also shown as references (Predescu, 2016).

Financial viability for small wind investment occurs in the region where the LCOE curve, computed for a specific investment value, is lower than the household energy price at the implementation location. The break-even point for a specific investment value is at the intersection of the respective LCOE curve with the line representing the household energy price. Beyond this point toward higher wind speeds, the savings obtained when using small wind technology brings long-term tax-free profit and savings to the investor. In countries where the household energy price is lower, financial viability can be reached at smaller specific investment costs and higher annual average wind speeds, which limits the geographical area where grid-connected small wind systems can be efficient. This analysis shows that in most situations, SWTs cannot compete with residential PVs in terms of economic viability (European Court of Auditors, 2018). Even at sites with high wind speeds, the cost reduction required to achieve viability is still substantial. Taking the best case from Bryne (2017) as a close-to-optimal performance example with a capacity factor of 33 %, the investment cost would need to be less than EUR 6000 per kilowatt (USD 6900 per kilowatt) for the LCOE to fall below EUR 0.20 per kilowatt-hour (USD 0.23 per kilowatt-hour), which is typical for residential retail electric rates in many European countries. This illustrates the main conclusion from the above analysis: SWTs may be viable, but only at very windy sites and with a serious additional effort to reduce the investment cost.

While Sects. 1–3 reported the status of the technology in terms of diffusion and costs, this section shifts the focus to the specific features of SWTs, which are the core of small wind systems. The philosophy with which this study has been prepared highlights those features that make SWTs different from utility-scale machines. This is important for introducing the resulting challenges that must be tackled to further progress SWT technology.

4.1 Typical features of small wind turbines compared to utility-scale turbines

Utility-scale wind turbines are usually located in clusters and in areas with high wind resources, from a few turbines to large wind plants located far (e.g., offshore) from the consumer. Although some utility-scale wind turbines may provide energy to the owner, they are typically owned by or provide power to a utility company. In contrast, SWTs are typically owned by the individual or organization that will use the power, such as a home or business, and are installed close to those loads. Because the siting driver for SWTs is proximity to loads and not the optimal wind resource, the winds at these locations often have low average speeds; are highly turbulent; and are more likely to have obstacles nearby, which can create flow structures of a scale commensurable to that of the turbine. On the one hand, this usually leads to lower peak power coefficients, ranging approximately from 0.25 to 0.40 (Wood, 2011), compared to values higher than 0.5 for utility-scale machines (Veers et al., 2019). However, full transparency regarding the real efficiency of SWTs is often missing. For example, in a relatively recent study, it was shown that 15 out of 43 manufacturers claim a power coefficient above the theoretical maximum or Betz–Joukowsky limit (Simic et al., 2013). Notwithstanding this, it is undisputable that the peculiar environment these rotors work in implies that SWTs must be specifically designed to work effectively in both low- and turbulent-wind-resource conditions. The implications of these peculiar working conditions are many and involve all aspects of turbine design and operation, as summarized below.

4.1.1 Aerodynamics

The combination of dimensions much smaller than those of utility-scale machines with turbulent winds may present significant problems for the aerodynamics of SWTs. First, the resulting low Reynolds numbers (Re) may cause a laminar separation bubble, which is associated with a local maximum of the drag coefficient in the polar and a reduced lift-to-drag ratio () (Selig, 2003). The presence of transition and the relative impact of inflow turbulence on it is key for airfoil performance (Abbott and Von Doenhoff, 2010). This has many implications for design, including the fact that airfoils for SWTs must be selected from those that provide good performance at low Re numbers, which favors airfoils with lower thicknesses that are, however, more sensitive to stall. A compromise in this regard must be pursued. The presence of transition makes the dependent on Re and thus is particularly challenging for blade designers. Because the angle needed for maximum is also Re-dependent, a constant-pitch turbine would not operate at maximum efficiency at a constant tip-speed ratio, making the control strategy in below-rated conditions more complicated (see the following subsection).

The aforementioned issues are particularly challenging in terms of proper simulation. Panel methods usually employed by companies to define polars likely fail to correctly model these phenomena in many instances, especially in the near- and post-stall regions. However, accurately modeling these phenomena is crucial for SWTs, particularly stall-controlled ones (Papi et al., 2021). High-fidelity models used in academia are often not affordable for SWT companies, and airfoil selection is therefore often based on published performance data. Examples of airfoils with good performance characteristics at low (around 5×105) Reynolds numbers can be found in Gigue`re and Selig (1998) and Timmer and van Rooij (2003). Even high-fidelity turbulence models, however, often do not predict lift and drag accurately in the presence of transition, let alone laminar separation, and the designer should rely on lift and drag data measured in reliable wind tunnel tests (Van Treuren, 2015).

The problem of low Reynolds numbers is further exacerbated by the possible installation of SWTs at high altitude (Pourrajabian et al., 2014), where the air density reduction can substantially reduce Re (up to more than 10 %), bringing it to those values where the effect of transition is more relevant. In this sense, it has been shown that the correction methods proposed in the standards (wind or power correction) often fail in correctly representing reality.

The influence of blade roughness, due to insect accumulation in dry areas or leading-edge erosion for example, also differs between SWTs and large turbines. Holst et al. (2016), for example, discuss the effects of roughness by comparing lift polars of low-Re airfoils to high-Re utility-scale wind turbine airfoils. Experiments in that study revealed lift deficits of up to 50 % and confirmed the importance of a proper profile selection. In addition, simulations showed that roughness can reduce AEP by up to 50 %. Furthermore, roughness sensitivity could lead to premature separation, especially near the blade root that is characterized by highly three-dimensional flow (Bangga et al., 2017). Thus, employing airfoils with good aerodynamic characteristics for the specific blade span and expected operational regime is compelling.

4.1.2 Control

Large wind turbines have yaw-drive mechanisms to align the rotor to the mean wind direction. Such devices are much more expensive for SWTs, especially for small rated power values (10 kW or less): in these applications, some form of free or passive yaw has been typically used. The most popular options are then a tail fin or the use of a downwind rotor, e.g., SD Wind (SD Wind Energy, 2022), Skystream (XZERES Wind Turbines, 2022), Carter Wind (Carter Wind Energy, 2022), and others. The downwind configuration solution is experiencing a revival for some specific applications in utility-scale machines, especially for floating offshore applications (Bortolotti et al., 2021). For larger turbines, the same yaw-drive technology in use for utility-scale machines is instead being increasingly applied.

Another control actuation commonly found in large wind turbines is the blade pitch system that can both regulate power and slow down the rotor for overspeed protection by aerodynamically changing the blades' angle of attack. However, pitch control is often not available at the scale of SWTs for economic reasons. Designing and manufacturing a fail-safe pitch system within the physical constraint of a small hub and the capital cost constraints needed to keep an overall low LCOE are one of the biggest challenges for the SWT industry. The need for a redundant brake mechanism, in fact, translates into either having independent pitch actuation (as for the utility-scale machines) or an oversized mechanical brake that could bring the rotor to a stop in the case of grid connection failure and associated runaway rotor. Both options have proven to be prohibitively expensive in the DWT space thus far, and more economical solutions for avoiding overspeed that have been widely adopted include stall regulation and/or rotating the rotor out of the wind direction via a furling mechanism. An attractive option for smaller SWTs is “electromagnetic braking” by shorting the generator output (McMahon et al., 2015). This obviates the need for a mechanical brake. Several current commercial SWTs such as the Bergey XL 15 (Bergey Wind Power, 2022) use this cost-reducing strategy. Regarding active pitch, however, a recent study (Papi et al., 2021) highlights how the use of advanced pitch-to-feather control strategies can significantly improve the performance of SWTs through more effective power regulation. It is speculated that the aerodynamic power coefficient could be improved significantly to reach CP≈0.5, which, together with simpler and therefore more accurate aerodynamic modeling performance, could then justify the higher cost of pitch actuation in a SWT. Also, another study (Papi et al., 2022) showed that a pitch control strategy can reduce peak loads in extreme conditions, thus potentially leading to lighter and more cost-effective blade designs. Blade pitch can also help with start-up torque at low wind speeds, whereas a fixed-pitch rotor must rely on its low wind speed and high angle-of-attack performance to overcome the resistive torque of the drivetrain and generator. A quick starting characteristic is crucial for SWTs because they tend to have more start and stop events compared to their larger counterparts due to higher turbulence levels and lower average wind speeds.

Due to the aforementioned technical and economic issues, stall control is still largely used in SWTs. This latter strategy, however, generates peak loads on the blades that are relatively much higher than those seen in utility-scale machines because the pitch cannot be varied in parking conditions. In addition to the lower efficiency in terms of regulation across the functioning range, the stall control strategy inherently introduces difficulties in predicting the aerodynamics of SWTs because three-dimensional flow aspects and unsteady characteristics make the near- and post-stall regions of the polar curves difficult to capture in aerodynamic models, especially in engineering methods (which can be economically used during the design phase). These difficulties are further compounded in the case of passive-yaw configurations. Skewed inflow and dynamic wake physics are still a topic of research in the wind energy community (Ning et al., 2015; Schepers et al., 2021) and in the case of SWTs, given their more dynamic nature (e.g., higher yaw rates, rotational velocities, and passive yaw), introduce further nonlinearities and unsteadiness in the rotor and tail induction fields, rotor aeroelasticity, and overall turbine response.

4.1.3 Structural design and (scarce) aeroelasticity modeling

In the field of large wind turbines, the use of aeroelastic simulation tools has been a consolidated practice for years (Bottasso et al., 2006) and is required for the certification of the machine itself. In the case of SWTs, the common approach up to a few years ago was to build stiff blades characterized by high safety factors in the structural design in order to avoid significant aeroelastic effects. As discussed, however, somewhat larger SWTs (from about 60 kW and up) are now practically equal in complexity to large wind turbines (e.g., they usually have a variable-speed pitch-torque control system and an active yaw control system and, because they often have a single actuation system for the blades, for safety they require mechanical brakes for the emergency stop). In addition, they are often designed for low to medium wind speeds, so the blade is very large (for the 60 kW blades, it is possible to reach 14–15 m). The experience of many authors of this paper, who had the opportunity in the last decade to collaborate with the small or medium enterprises (SMEs) producing these rotors (IEA, 2014), shows that the use of aeroelastic simulation tools is important to ensure a quality, safe, and economically sustainable project but is still very uncommon. One of the few aeroelastic analyses of a 5 kW turbine is described by Evans et al. (2018). The less frequent use of aeroelastic models in industry is due mainly to a lack of experience of these companies, which very often come from other industrial fields (e.g., producers of boats or heavy mechanical systems) where other design tools such as finite-element codes are primarily used. These companies are often not aware of the availability of good aeroelastic tools in the public domain (e.g., OpenFAST from the National Renewable Energy Laboratory, NREL; NREL, 2022). Finally, another limitation to the use of aeroelastic simulation tools for SWTs is connected to the lack of easy-to-handle post-processing tools. In fact, standards require the designer to simulate the wind turbine in power production for different wind values and gusts, but also for a variety of other operating conditions (starting phase, normal and emergency shutdown, transportation, faults, etc.). This results in a few thousand simulations that must be analyzed to extract maximum loading values for the various sub-components of the wind turbine, including blades, tower, and drivetrain, but also pitch and yaw, air gap in the generator, supports, bearings, brake discs, foundation, etc. In turn, these loads, together with fatigue loads and stress range cycles, need to be delivered to the different partner manufacturers. This process therefore requires automated tools and specific skills that are not always available outside academia or large manufacturers.

4.2 Innovative concepts and vertical-axis wind turbines

Whereas conventional horizontal-axis wind turbines (HAWTs) have become the reference technology for all scales up to 15 MW or higher, alternative concepts are still being proposed for SWTs (Damota et al., 2015).

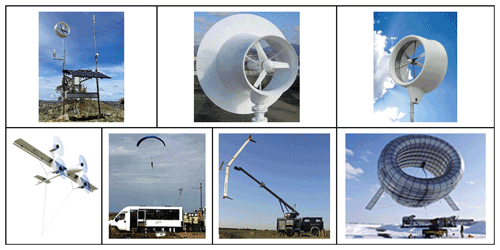

A popular modification to small HAWTs is to enclose the rotor with a diffuser to induce more airflow through the blades and thereby increase the power output. This produces a diffuser-augmented wind turbine (DAWT), some examples of which are shown in the first row of Fig. 10. Adding a diffuser is indeed more attractive for small turbines than large ones because the additional structural and wind loads on the latter are likely to be excessive. A diffuser is a relatively simple modification to basic turbine design, but it is still not clear how to optimize the diffuser and rotor to extract maximum power and whether the extra power is worth the cost of the diffuser. An interesting review demonstrating the enduring fascination of the concept has been recently reported by Bontempo and Manna (2020). There are other advantages of DAWTs: the diffuser may contain a blade if it detaches from the rotor and probably make the turbine quieter and less harmful to birds. These may well be significant advantages for DAWTs in urban settings (Micallef and van Bussel, 2018). At least two companies have recently commercialized small DAWTs, as showcased by Evans et al. (2020) and Visser (2020). They have found a wide range of applications from remote communication systems where the turbine partners a photovoltaic system to more common stand-alone systems.

Beyond other pioneering studies on novel energy-conversion systems such as DAWTs, most of the research on novel SWT architectures has been directed to vertical-axis wind turbines (VAWTs) (Aslam Bhutta et al., 2012).

Among these, drag-type rotors like the Savonius turbine (Akwa et al., 2012) are relegated to very small applications due to their low power coefficients and high mass-to-power ratio. Nevertheless, thanks to their simplicity, Savonius VAWTs are still considered suitable in remote rural areas (e.g., the first electrification of developing countries) (Senthilvel et al., 2020).

On the other hand, despite a long absence from research agendas after the first generation of research culminated in the mid-1990s, lift-driven VAWTs (or Darrieus concepts) are being increasingly studied (Bianchini et al., 2019). Despite popular claims, the new understanding of the complex aerodynamics of Darrieus VAWTs achieved in the last decade has proven that these machines can achieve power coefficients comparable to those of small HAWTs (Bianchini et al., 2015a). More importantly, VAWTs present several advantages for small-scale applications, namely an intrinsic insensitivity to wind direction, misaligned flows (Bianchini et al., 2012), or turbulence (Balduzzi et al., 2020) as well as lower acoustic noise generation associated with generally lower tip speeds (Möllerström et al., 2016). The advantage of low blade speed, however, is offset by the need to have a physically bigger, and therefore more expensive, generator and mechanical brake. In addition, VAWTs allow for a variety of design solutions, which are considered aesthetically pleasant by the public and thus also suitable for integration in buildings (Dayan, 2006) or with other infrastructure such as streets (Khan et al., 2017). Therefore, a variety of small manufacturers entered the market either with downscaled VAWTs or with alternative concepts specifically intended for use on rooftops (Mertens, 2003). Among others, one concept that is receiving increasing attention is the exploitation of the so-called Magnus effect, which is a phenomenon associated with a solid object spinning in a fluid. This concept has been studied for both HAWT (e.g., Sedaghat, 2014) and VAWT (Shimizu, 2013) designs. The potential advantage of these solutions lies in the fact that they can operate in relatively low winds (Bychkov et al., 2007), thus covering a range of winds not typically exploited by conventional wind turbines.

For very small VAWTs (<3 kW), recent designs chose high-solidity rotors, i.e., rotors with larger chord-to-radius ratios, mainly because of the need for sufficiently long chords to increase the aerodynamic forces and the Reynolds number. Based on recent analyses, this aerodynamic solution seems to provide unprecedented specific power values for small rotors (Bianchini et al., 2015a). On the other hand, these models showed the significant shortcomings of existing simulation models (Bianchini et al., 2019), which were resolved largely by the new understanding of the role of flow curvature effects (Bianchini et al., 2015b, 2016). Renewed research efforts are being undertaken to determine whether VAWTs can fit the scope of distributed energy production in complex installation areas, as testified to by the recent EU project (Aeolus4Future, 2022). Parallel to these research trends, VAWTs are being investigated for deep-water offshore applications with floating substructures (Paulsen et al., 2013). The more favorable structural loads of the VAWT architecture and the possibility of placing the generator on the floating platform – and thus lowering the system's center of mass – may lead to smaller floating supporting structures, better control, reduced logistics and capital cost, and ultimately a lower LCOE (Arredondo-Galeana and Brennan, 2021). In the realm of offshore SWTs, floating VAWTs could be deployed in some niche applications like integration with beacons at the entrance of a port. A recent book, for example, explores the relationships between small wind and hydrokinetic turbines (Clausen et al., 2021). Overall, despite the benefits that could be provided by VAWTs in some applications, they still lack both theoretical understanding and technical maturity compared to HAWTs. Whereas the theoretical gap could be overcome by modern investigation techniques, gaining the same level of industrial maturity as HAWTs seems out of reach at this time. The potential impact of funded research projects at a national or a broader level could be relevant in proving the real prospects of the technology and driving their development.

Figure 11Currently proposed DAWT (upper row) and AWE kite archetypes (lower row). First row (from left to right): the Diffuse Energy Hyland 920 diffuser-augmented turbine as part of a remote power system for a communication tower (the 200 W turbine has a maximum diameter of 0.92 m; photo supplied by Dr Joss Kesby), HAWT with flanged diffuser (Ohya et al., 2008), DonQi urban windmill (photo credit: DonQui Global). Second row (from left to right): cross-wind or fly-gen (a.k.a. drag-power) devices (image credit: Windlift), ground-gen (a.k.a. lift power) flexible kite (photo credit: KPS), ground-gen rigid kite (photo credit: Ampyx Power), aerostat ducted wind turbine (photo credit: Altaeros).

Other touted devices that, at least on paper, have demonstrated the potential for low LCOEs are airborne wind energy (AWE) kites (Fig. 11). They propose to extract wind power either through cross-wind by using lift and therefore flying faster than the wind speed and carrying turbine generators on board (fly-gen) or by pulling and unwinding a tether connected to a generator on the ground (ground-gen). Other concepts expect to take advantage of very-high-altitude winds via buoyant aerostat ducts. None of these concepts has thus far demonstrated an economically viable power curve or has shown successful size scalability in real-world settings. Yet, there is significant momentum in AWE research, with some pioneering industrial products already on the market, and the applicability of these devices will likely be in the distributed wind space. While it is difficult to assess the real costs and LCOE of AWE kites due to their nascent stage, the key advantage they provide is the absence of hefty and expensive support structures while maintaining a generous rotor swept area. This would have favorable effects on the balance of station costs that have plagued the DWT industry to date; this is the main reason why they are mentioned here as potential actors of the small- and, more likely, distributed wind market of the future. The challenges these devices face are numerous, however, from flight safety and reliability to the efficiency of power generation and from the issuing of design and certification standards to their acceptance by public and aviation authorities, and only future deployments will indicate whether they can compete in the DWT market.

4.3 Turbine archetypes and design standards

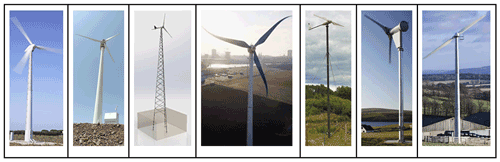

Unlike the typical utility-scale, three-bladed, upwind machines, SWTs have not coalesced into a dominant archetype, with many different layouts still being offered on the market. The variety of archetypes (upwind vs. downwind; HAWTs vs. VAWTs; two vs. three or more blades; even one like PowerHouse Wind, 2022; active pitch vs. stall-controlled; etc.; see Figs. 12 and 13) creates a challenge for the design standardization and certification of SWTs (Damiani et al., 2022). This challenge is made stronger by the intention of standards to facilitate the development of SWTs at relatively low cost; the “simplified loads methodology” (SLM) in IEC 61400-2 for small horizontal-axis turbines is the main example.

Figure 12Common HAWT archetypes found on the current DWT market. From left to right: upwind, active pitch and yaw (photo credit: Tozzi Nord); upwind, stall-controlled and active yaw (photo credit: Eunice); upwind, stall-controlled and tailed passive yaw (photo credit: NREL pix 49511); downwind, stall-controlled and passive yaw (photo credit: Eocycle – formerly XANT); upwind, tailed passive yaw, furling (photo credit: Bornay); downwind, pitch- or pitch-coning-controlled, passive yaw (photo credit: SD Wind, formerly Proven); downwind, stall-controlled, passive yaw and teeter (photo credit: Ryse Energy, formerly Gaia).

Figure 13Common VAWT archetypes found on the current DWT market. From left to right: Darrieus Troposkien (photo credit: Chava Wind), H-Darrieus (photo credit: Xflow Energy), H-Darrieus with helix shape (photo credit: PRAMAC), Savonius (photo credit: BE Wind), combined Savonius–Darrieus (photo credit: HiVAWT).

The lack of dominant archetypes complicates the development of standards and design tools for SWTs, resulting in a reduced refinement and robustness for all the archetypes as their counterparts for utility-scale machines.

Type certification for large wind turbines, which primarily follows IEC 61400-1 (IEC: International Standard, 2019a), are typically performed by large companies with extensive design teams who can afford multidisciplinary development departments, highly refined turbine-specific aeroelastic models, high-performance computing, and testing facilities. The much smaller companies that manufacture SWTs do not have access to such resources. For example, even though estimating the loads according to the design standards would require only a few hours of computational time with state-of-the-art engineering codes, these codes require resources and staff with very specific skills to be utilized correctly, and correlation to archetype-specific load measurements is needed to demonstrate confidence in the results.

The IEC standard for wind turbine design also includes the IEC 61400-2, dedicated to SWTs (IEC: International Standard, 2019b). It covers all mechanical and electrical subsystems and includes support structure and foundations as well as the grid connection (including power electronics where applicable). The section applies to wind turbines with a rotor swept area smaller than or equal to 200 m2 generating at a voltage below 1000 V AC or 1500 V DC and covers both grid-connected turbines and off-grid applications. IEC 61400-2 allows for a number of simplifications to the design and analysis of turbines, including the use of the SLM and a reduced number of design load cases (DLCs). However, the SLM currently captured in the standards is more than double the safety factor for ultimate loads, which may make the SLM process easier to use for the design phase and helps keep costs low but will create a heavier and more expensive product, which results in turbines that may not be competitive on the distributed generation market. By their nature, use of the SLM normally leads to a safe but over-designed product. For example, for very small SWTs, the critical DLC includes the gyroscopic loads on the blade roots and main shaft under yaw; however, in general terms our knowledge of the yaw behavior of SWTs is poor across the range of turbine configurations. The magnitude of the gyroscopic moment is given by a simplified load equation involving the blade moment of inertia, the blade angular velocity, and the yaw rate. Although the equation captures in principle the actual physics responsible for the gyroscopic moment (Wilson et al., 2008), the safety factor for this load is 3. The SLM stipulates the maximum yaw rate as a function of rotor area and then requires this to be multiplied by the maximum blade angular velocity. The limited information available on SWT yaw behavior (e.g., Wright and Wood, 2007, and Bradney et al., 2019) suggests however that high blade speed correlates with low yaw rate, but this is not used in the SLM.

As an alternative or if the turbine configuration is not covered by the SLM equations, then alternative simulation modeling or load measurements can be used, which may result in a more optimized final design. Additionally, many aspects of the turbine aeroelastic response that are missed by the SLM approach could, in principle, be captured by higher-fidelity aero-servo-elastic modeling. However, using aeroelastic modes for the design and certification of SWTs is challenged by the fact that while models are well tuned for active-yaw and active-pitch HAWTs, they are less validated for stall-controlled, passive-yaw HAWTs and progressively less so for non-traditional archetypes (e.g., teetering hubs, VAWTs, AWE kites) (Damiani et al., 2022).

Regardless of the initial design approach, the reliability of SWTs is guaranteed through duration testing, where at least 6 months of operation is required during which minimum operation at high winds is stipulated. The standard requires comprehensive documentation of the testing. In addition to the whole turbine testing, specific component tests are prescribed.

Some SWTs come with design variations. To limit the demands on the original equipment manufacturers, a full design evaluation is only required on a selected representative configuration. Other variations need only be evaluated or tested in the ways in which they are different from the representative configuration. Guidance on the conformity assessment, however, is rather limited in the design standards, and this has been lamented by the industry as an obstacle to the commercialization of new fleet products or in the case where changes to the product line, such as the use of a new manufacturing process for an individual component, may open the product to extensive work to maintain certification.

For power performance testing, IEC 61400-12-1 includes a normative Annex H specifically for the power performance testing of small turbines. This reflects the fact that testing according to the general standard using 10 min averages, where the complete wind speed range must be covered by sufficient data to minimize statistical uncertainty, can be a time-consuming and expensive process. To get around this difficulty, testing SWTs involves using 1 min averaged data, thus considerably reducing the time needed for testing, but also because 1 min averaging extends the frequency distribution of wind speed, making high-wind-speed data points more common.

The SWT test standard also covers battery charging. Procedures are prescribed that minimize the influence of the specific battery configuration and condition (state of charge). SWTs that use inverters for grid connection are tested together with the inverters, and the power measured is the power available to the consumer. Most SWTs lack a clear definition of rated power and wind speed; instead, a reference power is defined as the averaged power in the 11 m s−1 bin.

Comparisons of 10 min averaged power curves with those based on 1 min averaged data have been presented in Elliott and Infield (2014). Fortunately, the systematic distortion of power curves due to so-called errors in bins was found to be small. However, if the 1 min power curve is used together with a 10 min averaged wind speed distribution, then an error of 1.15 % in the estimated annual energy yield is shown in the study. To avoid this, the energy yield calculation should ideally be based on 1 min averaged wind speed data. Because the calculation of turbulence intensity depends strongly on the averaging period, it would be better for this aspect of site characterization to be based on 10 min data, even if the power curve itself is based on 1 min data as prescribed in the SWT test standard.

From this overview, it is clear that the SWT design standards can be substantially improved on multiple fronts, from the design requirements to the testing, validation, and conformity assessment. The preparation of a new edition of IEC 61400-2 has just started. It is anticipated that the SLM will be improved and there are likely to be further divisions of SWTs depending on size, power rating, and archetype. Rotor swept area combined with rotor orientation, type of power regulation, and type of yaw control, for example, can lead to a matrix organization to determine requirements for design load calculations, structural verification, and numerical model validation that would also depend on the experience of the numerical codes with the different turbine archetypes (Damiani et al., 2022). A rigorous differentiation of certification requirements that depend on the turbine configuration appears as the most urgent need in the design standards to arrive at a substantiated assessment of the load categories for SWT. All these desired changes should make the standard significantly more useful to the manufacturers and end-users of SWTs.

The transition to a more distributed production of energy, combined with the evolution of grids toward “smart” architectures and control logics, which are more resilient, is leading to an evolution in the way electric services are being provided. Distributed solar has already demonstrated wide-scale acceptance (IEA, 2019) in this more distributed energy system. While SWTs have yet to reach general acceptance, they can play a similar and supporting role. To become more commercially accepted, marked cost and performance improvements are needed. Although significant reductions can be achieved through understood technology improvements, additional innovations are needed that lie beyond our current knowledge of critical physics, with particular reference to turbulence, applicability of design assumptions, and the existing modeling and simulation capabilities. Cost reductions that have been demonstrated within the distributed wind industry show that with adequate investment, significant hardware cost reductions are possible (NREL, 2022). However, the generally low investment in small wind technology research and a lack of consistent and substantial incentive programs have relegated SWTs to niche applications with minimal economies of scale. The success of solar PVs, which has benefited from significantly more incentive programs than SWTs on the distributed generation market, demonstrates the importance of stable incentive programs of this type in achieving market share.

Among other considerations, a recurring research gap noted in many studies is that SWTs often fail to achieve predicted or published AEP. This is likely due to a host of considerations such as overly optimistic resource assessments, rotor underperformance at low wind speeds and during high turbulence, or poor final turbine siting. The two flow features, rotor underperformance in low winds and/or turbulent winds, are typical of installations on top of short towers and in proximity to natural or artificial obstacles.

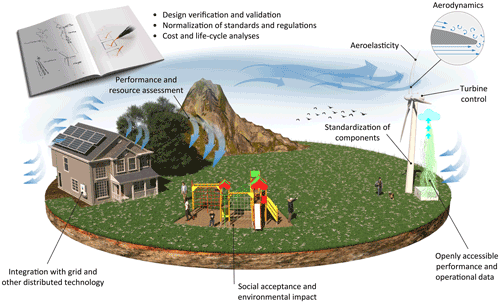

Based on the status of the technology described in the previous sections, the present study identifies five specific grand challenges (GCs) that must be overcome to spur SWT development and meet the globally expected demand for a wider variety of distributed energy resources. The grand challenges are visually presented in Fig. 14, which represents the graphical abstract of this study. To address these challenges, a number of unknowns and gaps to be filled are identified (Sect. 5.1). Future enablers (Sect. 5.2) are also suggested as the keys to elevate SWTs to a more mature technology.

Figure 14Visual synopsis on how the key enablers identified in this study may help tackle the five grand challenges for SWT technology.

Grand challenge 1 – improve energy conversion of modern SWTs through better design and control, especially in the case of turbulent wind

Because SWTs are typically installed in areas with lower (less energetic) and more turbulent wind resources, maximizing the amount of energy that can be harvested from the wind (i.e., maximizing the SWT's capacity factor) while ensuring turbine longevity and survival through infrequent high-wind events is critical. Many wind turbines have been shown to underperform in comparison to performance based on simulations. This is due to a combination of simulation tools that overpredict turbine performance, driven largely by the simplification of flow features that these turbines are subject to and the actual complexity of the oncoming flow. In particular, better insight into the impact of turbulence and gustiness on turbine performance is needed. This can be achieved with a combination of more detailed testing data and more advanced design tools capable of modeling the complex blade–flow interactions. Additionally, advancements focused to exploit oncoming winds more effectively, including the use of taller towers or the design of lower specific power rotors to better exploit lower winds, must be continued.

To this end, it is now possible to undertake multidimensional blade design to minimize starting time, blade mass, and noise while maintaining good power extraction and adequate blade strength (e.g., Sessarego and Wood, 2015). Among other aspects, blade mass is paramount because it correlates with manufacturing costs and blade inertia. In turn, the ability of a turbine to start quickly to maximize power extraction at low wind speeds depends on the inertia, as do the gyroscopic loads discussed above, giving this feature an importance that it does not have for large turbines. SWT blades are naturally stiff and benefit from additional centrifugal stiffening at high angular speeds, so further optimization should be possible. Because the gyroscopic loads are major fatigue (as well as ultimate) loads, an improved understanding of turbine yaw behavior should allow more optimized turbine design. This should be seen as the key challenge in the modeling of complex unsteady aerodynamics in the presence of passively yawing rotors, either downwind of the tower or yawed by tail fins.

Grand challenge 2 – improve prediction and reliability of long-term turbine performance despite limited resource measurements

Going beyond accurately optimizing and then predicting the power production of a SWT based on specific wind characteristics, for SWT projects to receive financing, the industry must be able to accurately predict turbine power production over the full life of the project. This accuracy of long-term performance prediction is needed to lower the risk associated with SWTs as seen from the perspective of consumers, insurers, city planning professionals, project financiers, and regulators.

Long-term performance prediction is built on a number of factors, primarily the turbine performance characteristics combined with accurate wind resource estimation and any changes due to local obstacles over the life of the project. Additionally, turbine availability due to mechanical, electrical, and weather conditions at the specific site must be considered in addition to long-term turbine reliability and performance degradation. Although not directly related to turbine design, the availability of spare and replacement parts, approved turbine repair technicians, company warranty commitments, and specific turbine location relative to all these factors will also drive long-term power generation.

Beyond corporate credibility of the installer and turbine manufacturer, long-term production reliability can be categorized in two main areas, i.e., wind-driven resource performance and turbine reliability. Discussions with the SWT development community have identified several key challenges to conducting low-cost but accurate resource assessments (Fields et al., 2016). These include the availability of low-cost anemometer and remote sensing; the lack of high-quality mesoscale-modeled wind speed data at heights typical for SWT installation; and the availability of validated and easy-to-run obstacle modeling to understand the potential impacts of local obstacles on the wind resource, especially in complex terrain (Duplyakin et al., 2021). Once an accurate assessment of the resource at the site in question is available, typically for a model year, additional parameters such as the conditional changes over time, growth of obstructions such as tree cover, and potential weather-driven availability reduction will need to be added. Tools making resource recommendations must also be verified, providing confidence to installers, consumers, and the financial community (Tinnesand and Sethuraman, 2019).

Many turbine manufacturers can point to turbines that have operated reliably for many years, but to be successful in today's market, a long turbine life must be balanced with economic viability (see GC 3). The second element of this challenge is developing methods that prove that SWT technology will operate reliably over the turbine's design life. For example, the SLM of IEC 61400-2 mandates a simple determination of the total number of fatigue cycles experienced by the blades of a SWT. Because of the higher angular velocities of SWTs, the fatigue cycles for SWT blades are on the order of 100 times the number for large turbine blades. Despite this, the standard does not mandate fatigue tests for small blades, and there is not strong operational evidence that fatigue is a major issue for most SWT blades. On the other hand, the fatigue load case in the SLM appears to be very conservative (Evans et al., 2021), which increases turbine costs and may not identify the likely locations for fatigue-driven failures in operating turbines. Addressing this challenge will center on developing a better understanding of the likely failure modes of SWTs, improved knowledge of the role of yaw behavior in generating gyroscopic fatigue loads, the development and use of validated design tools that address the likely failure modes, and standards and certification processes to help ensure that turbines operate reliably over their design life. This improved understanding and these improved tools will also need to be validated for the wide array of SWT configurations, including free and damped yaw. For the future SWT market to be successful, this effort will need to be accepted by large-scale financial organizations, which are driving investment in distributed-scale power generations.

Grand challenge 3 – improve the economic viability of small wind energy

For a SWT to be economically successful, it must provide reliable power at a cost comparable to other similar technologies, such as distributed solar PVs, and be acceptable by the market. A reduction in the LCOE can be achieved by balancing better capacity factors (see GC 1) and reducing unit installed cost. Reductions can come from design optimization; using new materials and manufacturing techniques; developing standardized solutions for components that can be applied across multiple turbine models, such as power inverters; and promoting or incentivizing production economies of scale. Moreover, improvements in installation techniques, reducing the cost of foundations, and other related balance-of-station costs will be needed.

Many strategies have been considered to lower the cost of turbine hardware, with some solid success in specific turbines. A balance must however be made to optimize lower turbine costs, which is largely driven by reducing turbine materials and ensuring successful operation over the turbine's designed life (see GC 2). This optimization must also be balanced with international standards, which may drive up turbine system costs through the SLM. For example, tools used to predict the impact of turbulence on component fatigue while load-reducing turbine control, such as adopting pitch regulation typical in larger rotors, can also help ensure long-term turbine operation while optimizing turbine material needs. The expanded use of validated aeroelastic design tools will also become more critical to help optimize this balance of reliability and low cost.

Recent increases in commodity prices as well as supply chain interruptions are causing increased costs for most SWT manufacturers. Although some of these challenges could be overcome with expanded manufacturing, leading to larger economies of scale and increased industry purchasing power, expanded research into material substitution for high-cost or hard-to-access materials would help lower and stabilize turbine manufacturing costs. Expanded work in aligning component supply across multiple SWT vendors may also help address some high costs and lower component availabilities, especially if supply chain disruption becomes more common.

Overall, a lower LCOE will also help communities access SWT technology (see GC 5), allowing wind technology to play a more active role in addressing issues of energy poverty and energy access while reducing the needs for financial incentives, which typically favor wealthier consumers.

Grand challenge 4 – facilitate the contribution of SWTs to energy demand and electrical system integration